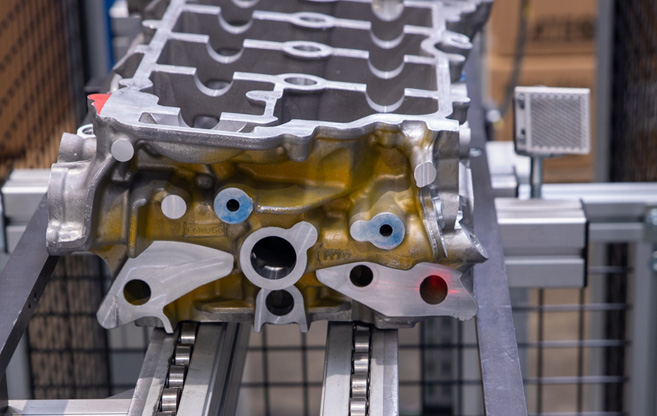

Flexible bushing assembly

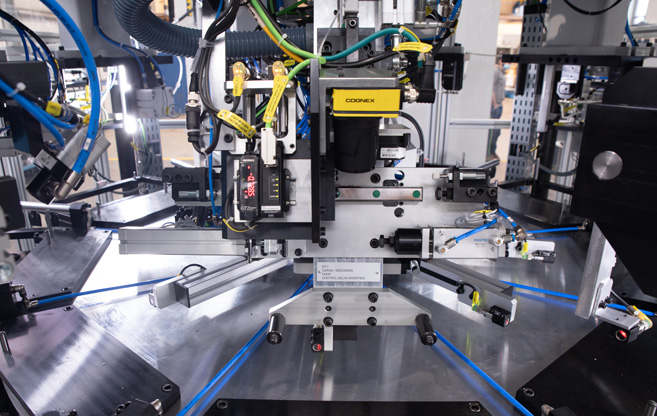

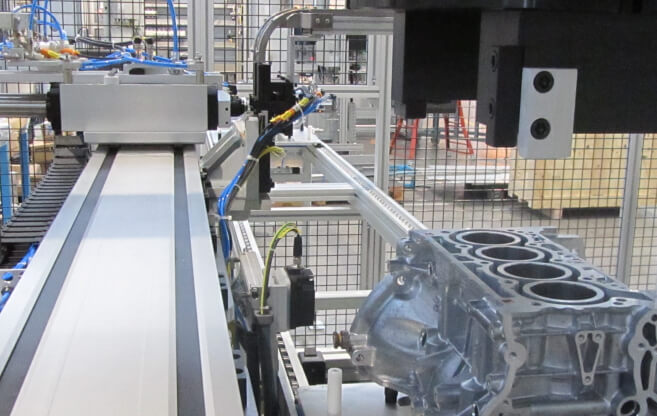

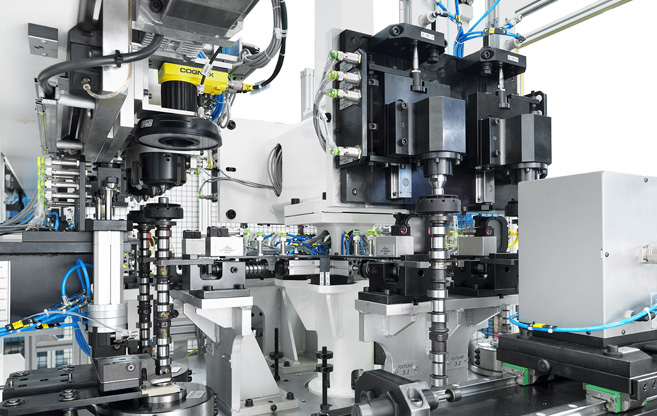

We assure the controlling of all pressing processes, supported by the integration of electrical presses in most of our solutions.

How it works

Our Solutions

Grounded in our large engineering experience, we have developed reliable, compact and scalable solutions to fit our customers needs. Depending on the production planned, footprint or automation requirement, two product categories are identified.

-

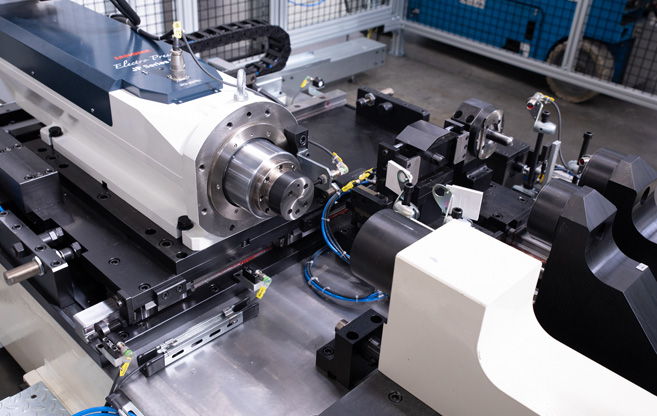

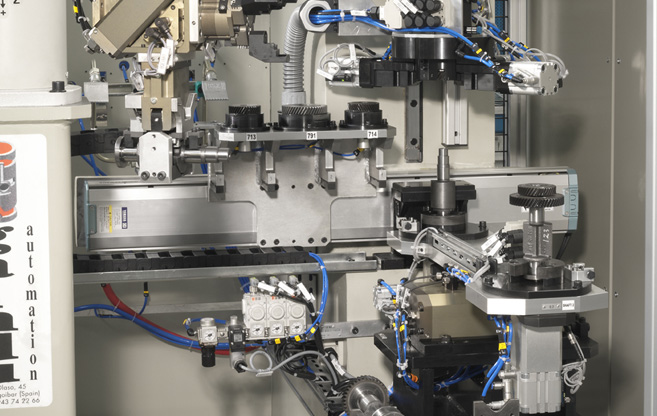

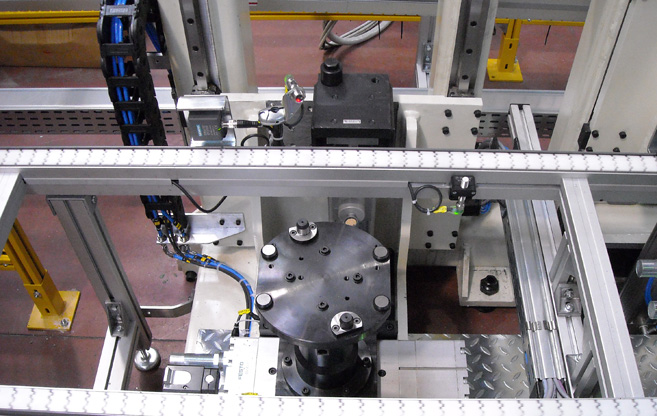

Unitary

A cost effective sensible solution for low-medium production projects.

The unitary machine combines the benefits of the quality assurance with a highly compacted solution that allows a small footprint required layout.

The integration of all components on a single frame station speeds the entire set-up proccess up. Quick and effortless machine installation at customer’s plant, makes it for shorter delivery times.

-

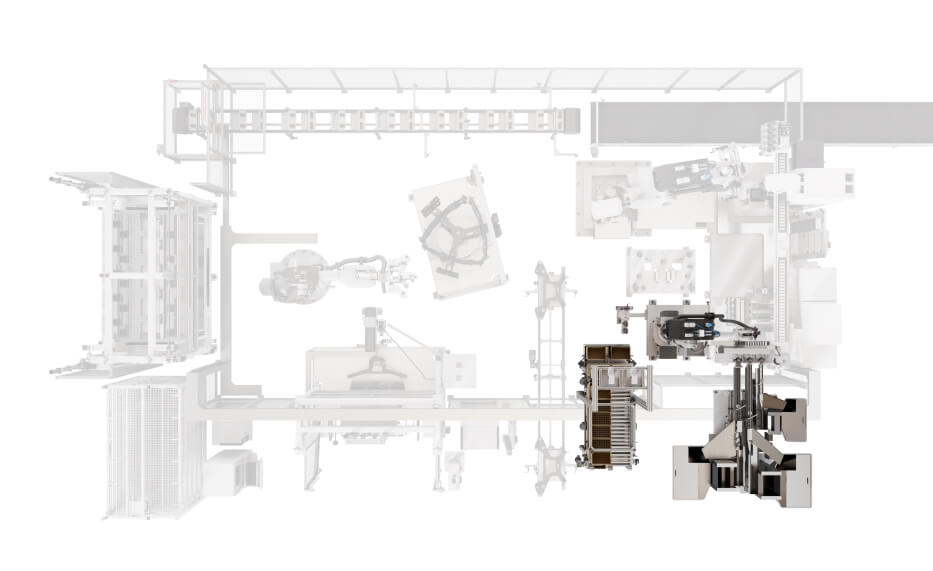

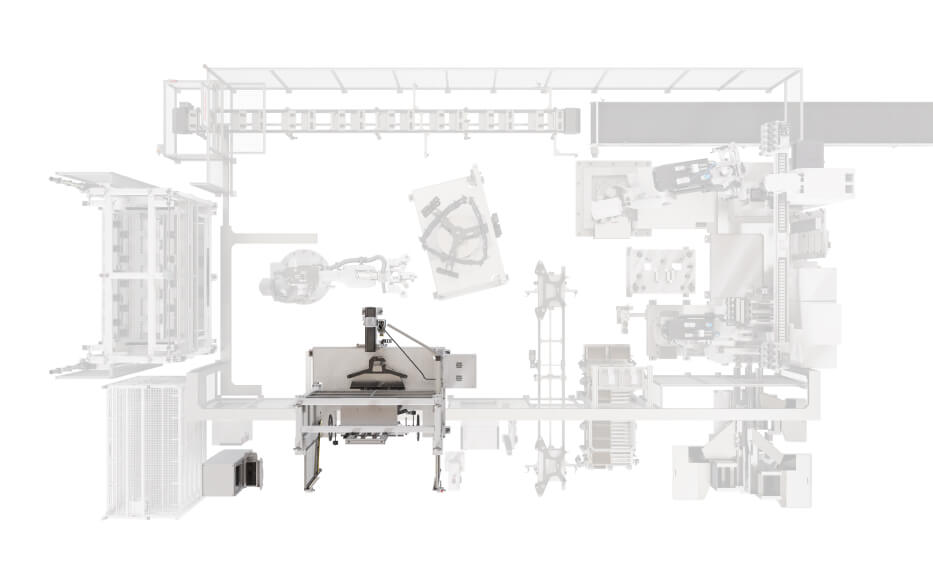

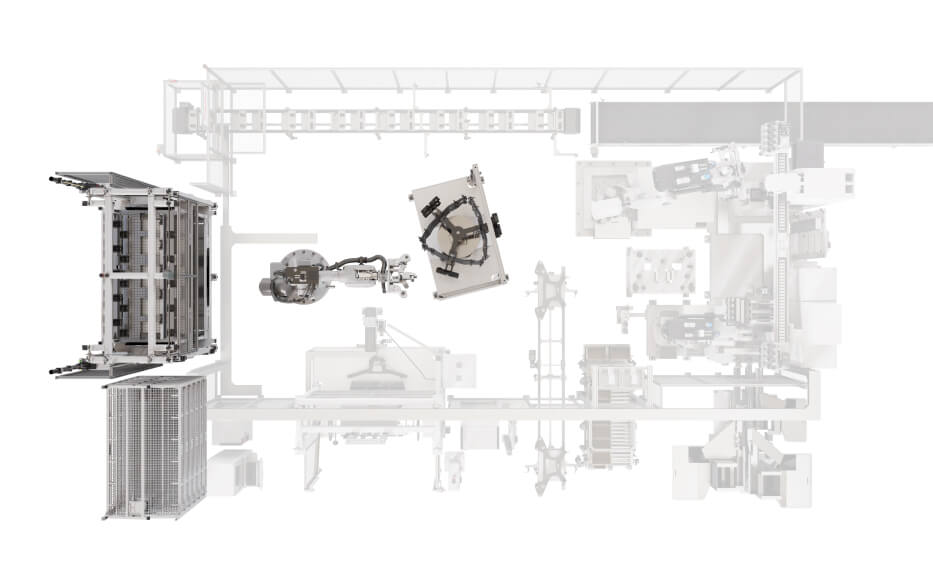

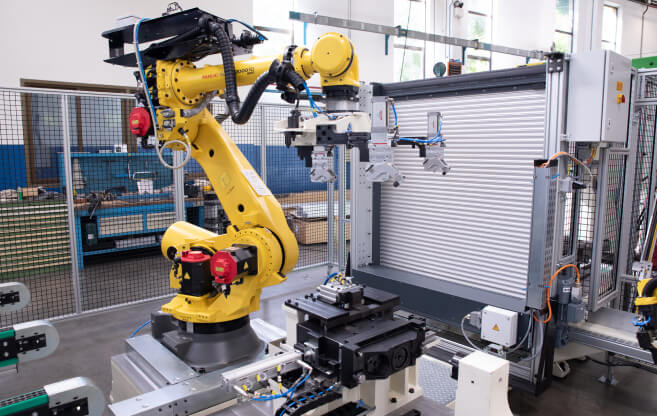

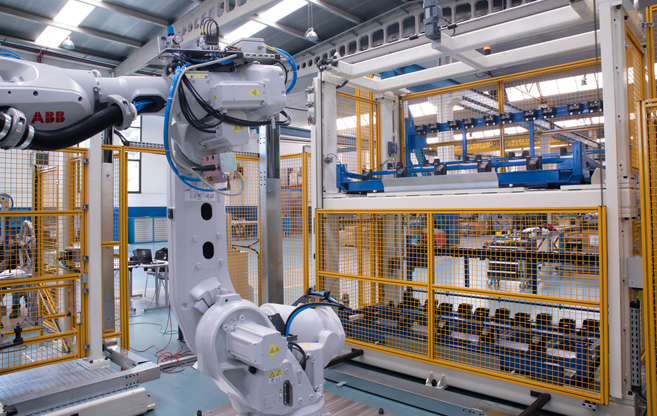

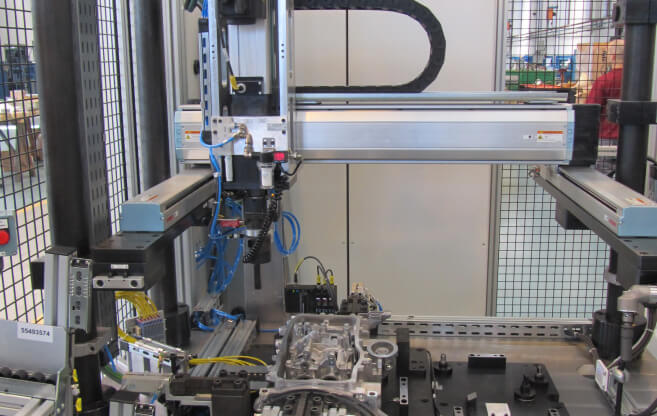

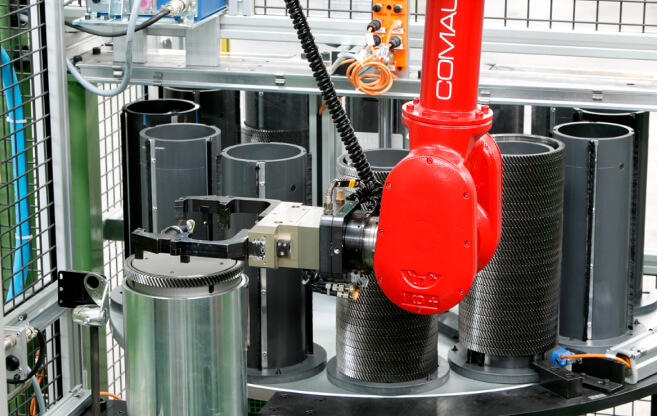

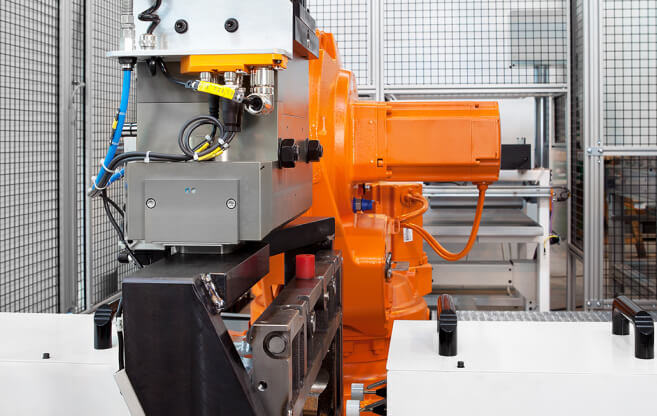

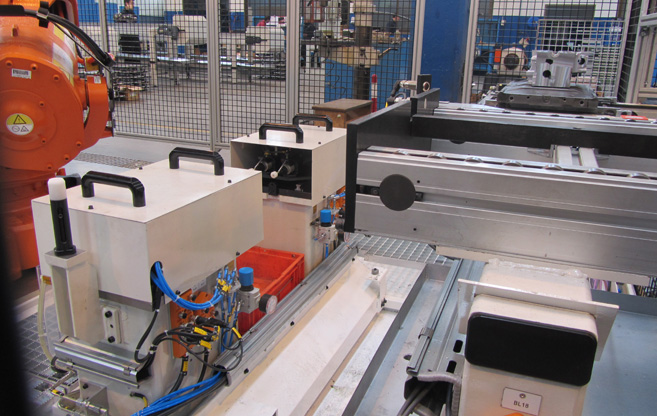

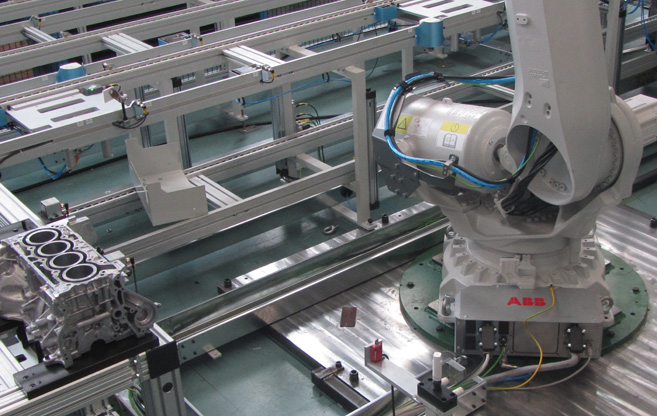

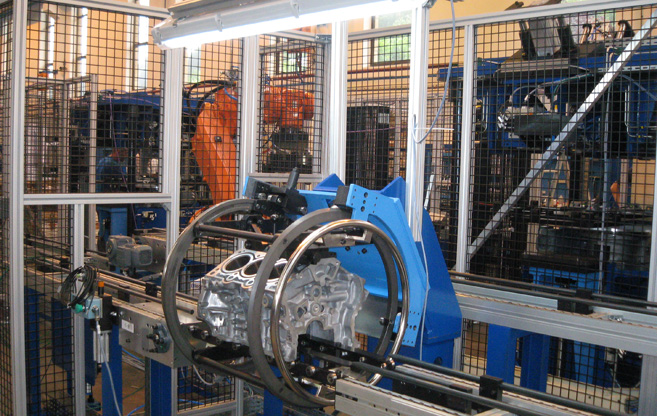

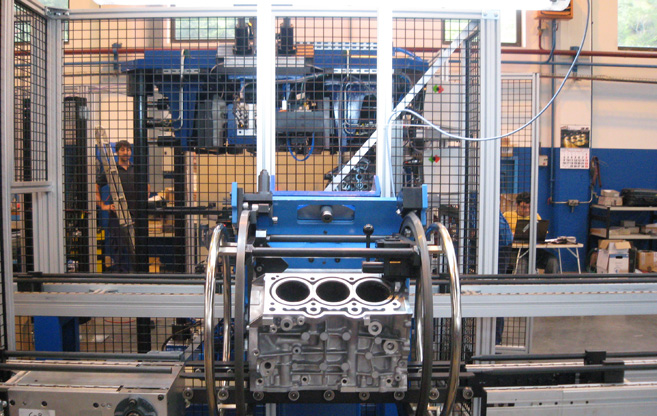

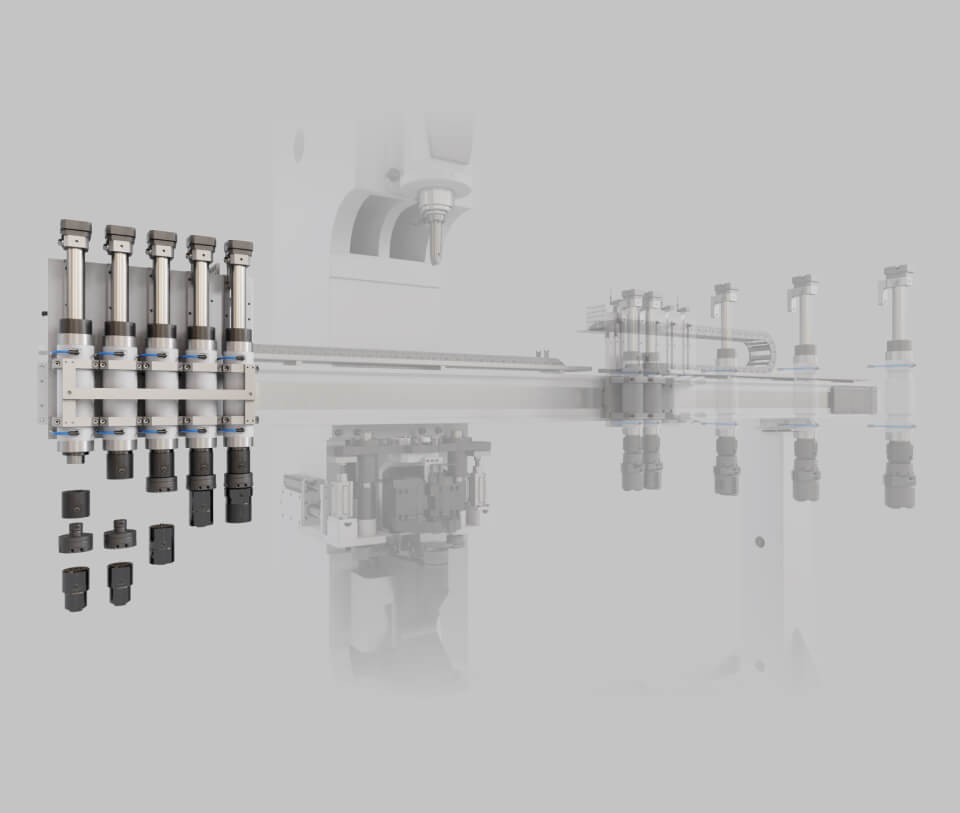

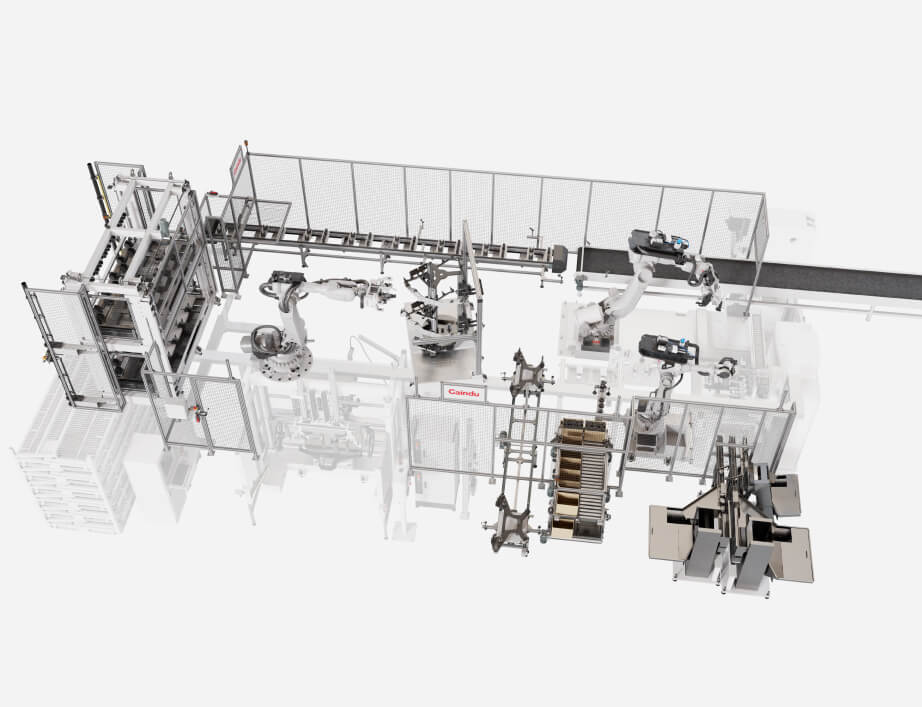

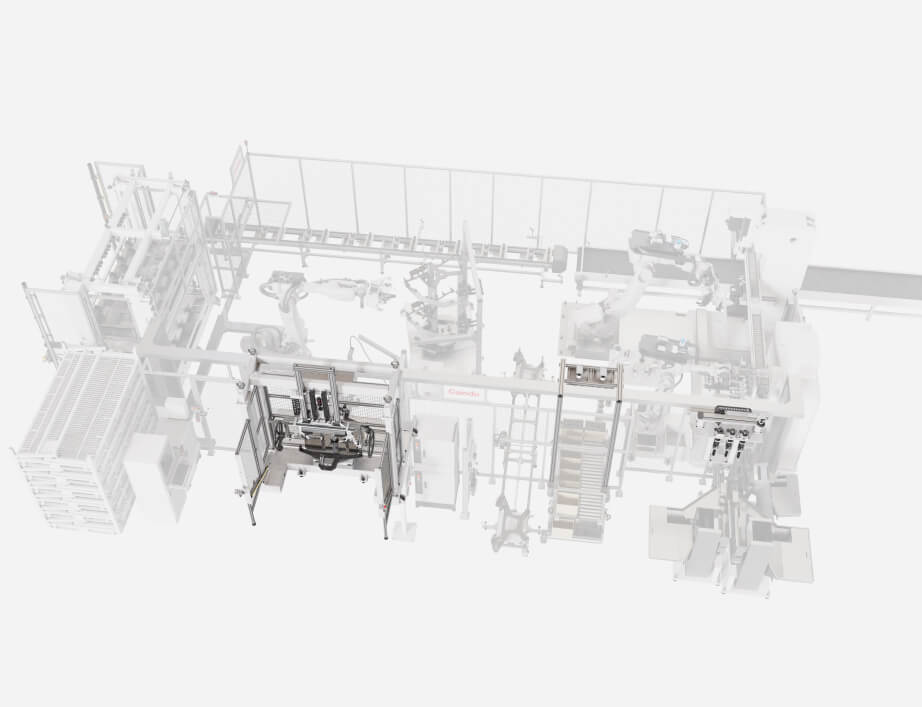

Robotized

The robotized solution represents all the advantages for a complete flexible production cell. The solution is specifically recommended for medium-high volume and medium-high mixed diversity management.

It is highly adaptable to customers needs and scalable in terms of automation, with manual loading or automatic loading options.

A robot operated cell that features almost limitless positioning for insertions and engineered to attend customer’s expectations.

Features

SCALABILITY

Variety of additional technologies

FLEXIBILITY

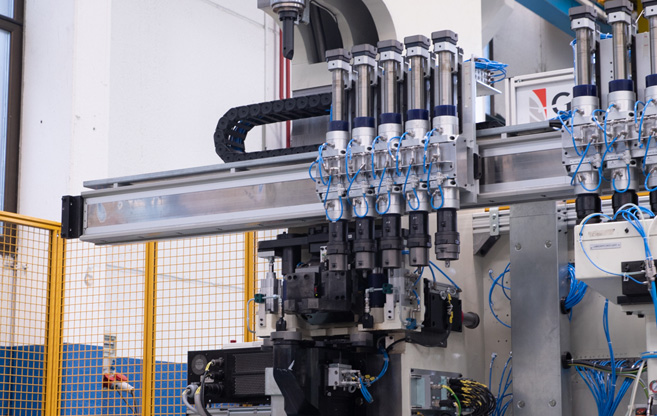

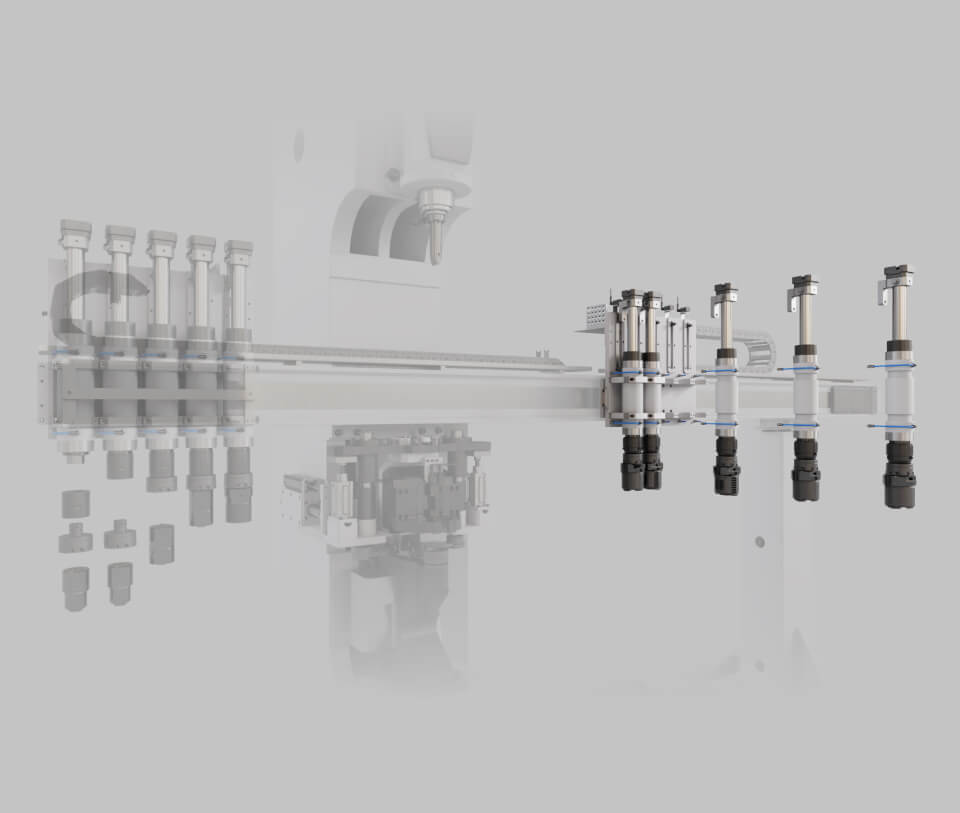

For high production rates, our quick change clamping fixtures allow for fast and reliable changeover, in manual or automatic mode.

In cases where the required diversity exceeds the basic configuration, the pressing nozzles can be quickly exchanged. This feature expands the opportunities for integrating different types of assemblies in the same productive cell.

Machine configurations available with up to 9 different pressing rams, enables a flexible mixed production free from changeover downtime.

Technologies

-

Automation Technologies

We offer integral solutions to optimize the productivity, being the automation of the loading/unloading and feeding of parts to the production systems a fundamental part of this process.

-

Assembly Technologies

After more than forty years of collaboration with the best manufacturers in the world in order to integrate the most advanced assembly systems in our installations, we are able to offer comprehensive solutions for the assembly and joining of components under the use of diverse technologies.

-

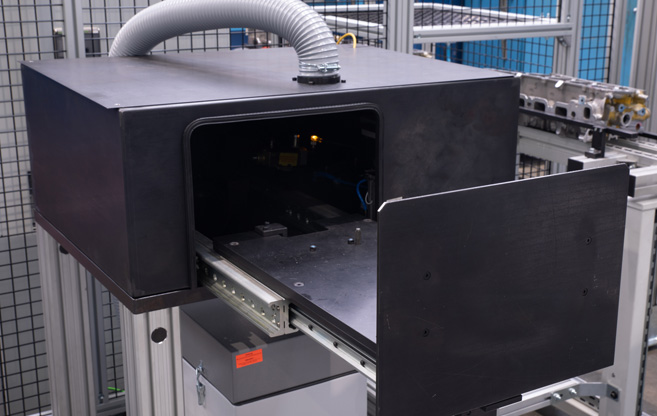

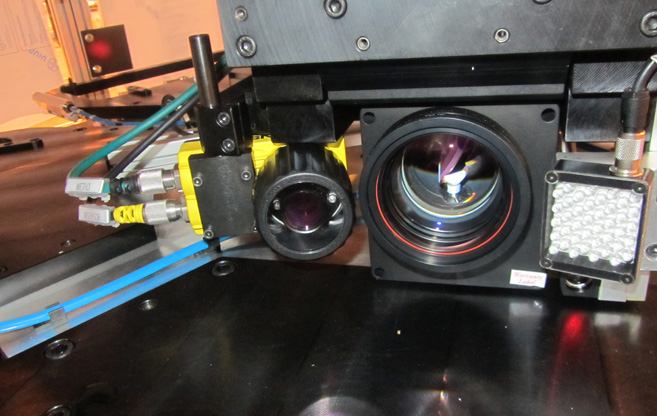

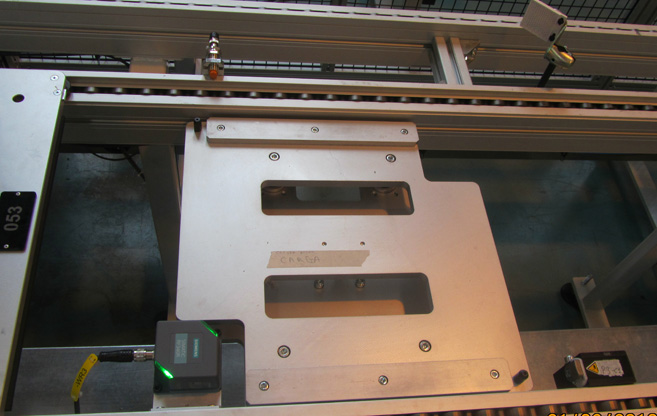

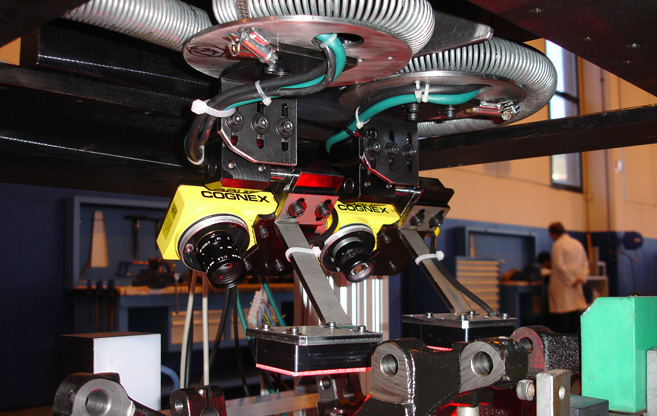

Traceability Technologies

Our cells include the means to completely trace the parts and ensure that the information is recorded for further processing. Some of the technologies used for this purpose include marking, reading and data storage.

-

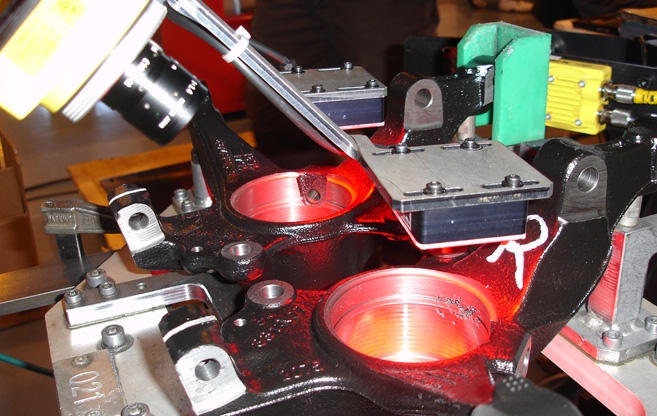

Testing Technologies

Quality assurance in our products and therefore in our customer's final product is an absolute priority for us. In this direction we work to offer the best quality control systems in different areas.

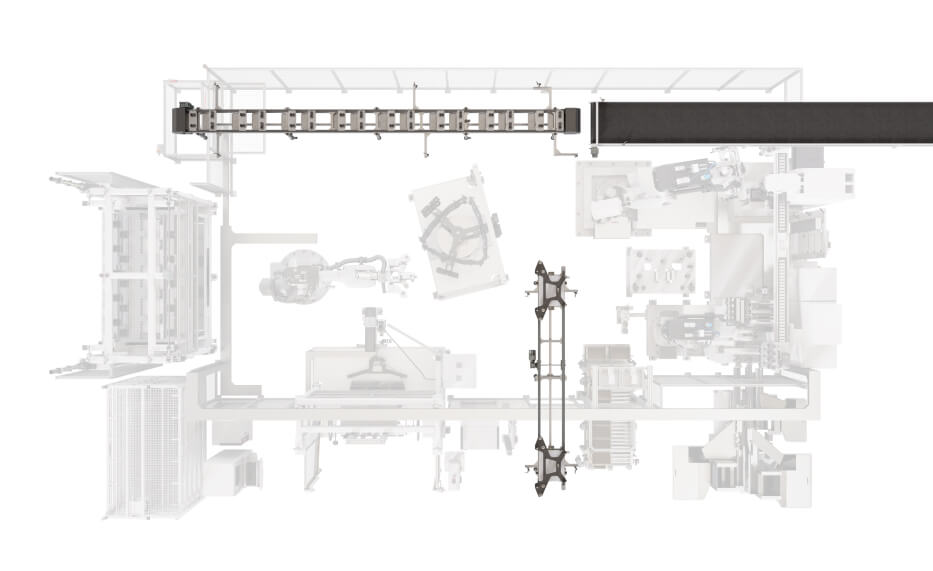

Conveyor

Conveyor

Robot

Robot

Feeding

Feeding

Palletizing

Conveyor

Conveyor

Robot

Robot

Feeding

Feeding

Palletizing

Pressing

Measuring

Lubrication

Pressing

Measuring

Lubrication

Marking

Reading

RFID

Gaindu Tracker

Marking

Reading

RFID

Gaindu Tracker

Visual Inspection

Vision

Vision

Visual Inspection

Vision

Vision

Applications

-

KNUCKLES

-

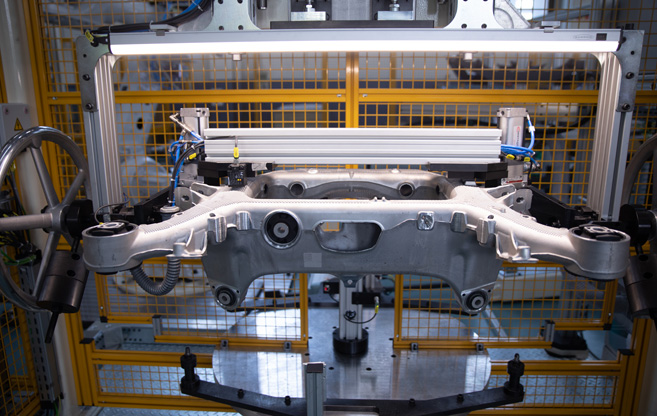

RLCAs

-

CROSSMEMBERS

-

SUBFRAMES

Case studies

Gaindu has collaborated to improve their production processes or undertake complex operations in an efficient way.

MORE ABOUT CASE STUDIESInterested in knowing more how we can help you?

CONTACT US