Laser welding

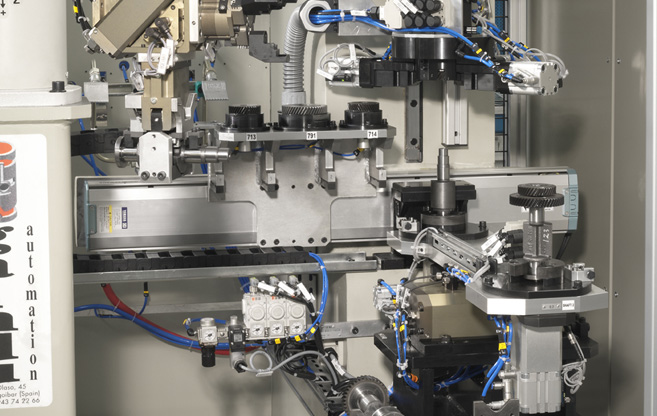

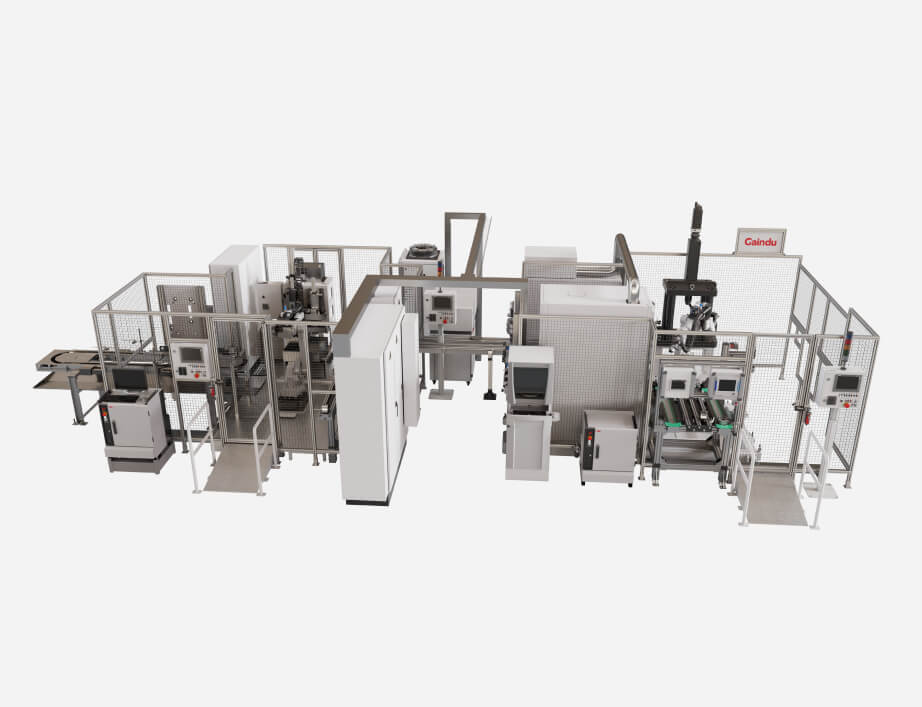

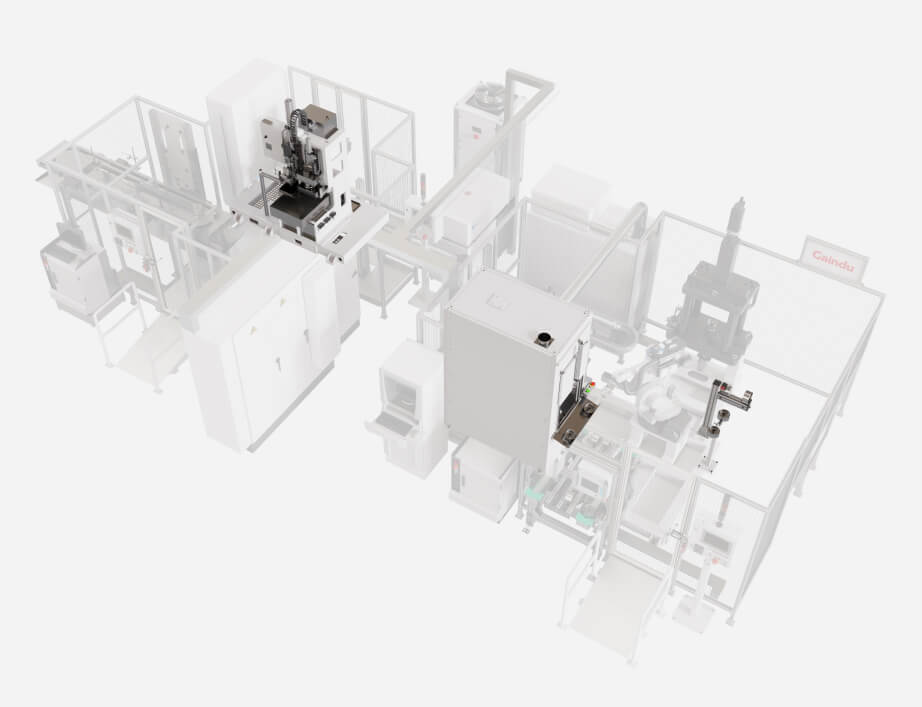

High precision combined assembly and welding machines on which we integrate equipment from the leading specialists in laser industry.

Our Solutions

By combining in-depth experience in press assembly processes with the most advanced laser welding solutions available on the market, we are able to offer a wide range of laser welding solutions. Our welding solutions are compact, reliable, scalable and solve complex problems with reliable and safe processes.

-

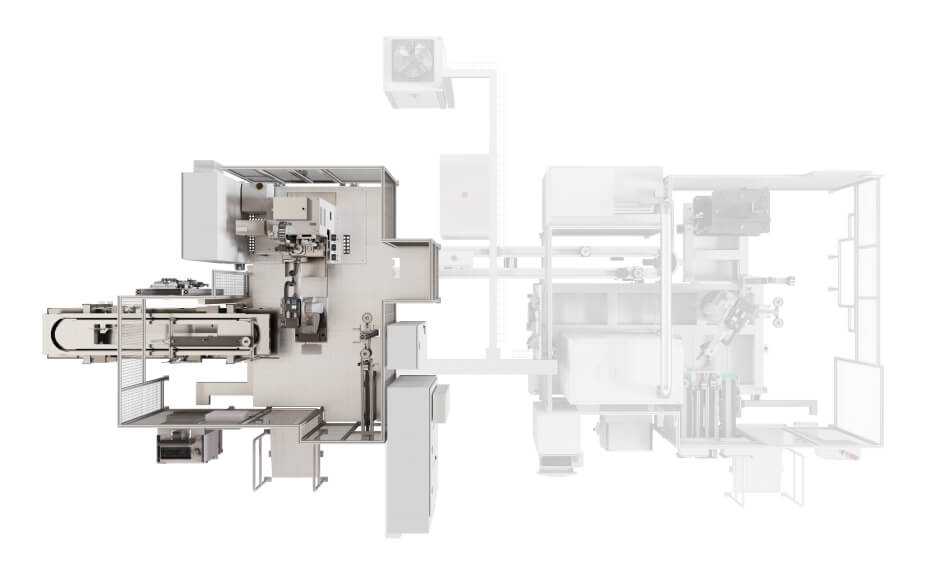

Manual

- For cases in which the required productions are very low (very small batches), it is possible to offer a semi-automatic solution in which the robot is not required for loading/unloading tasks.

- This solution allows for a lower initial investment, which in the future has the possibility of increasing the equipment as the required production rises.

-

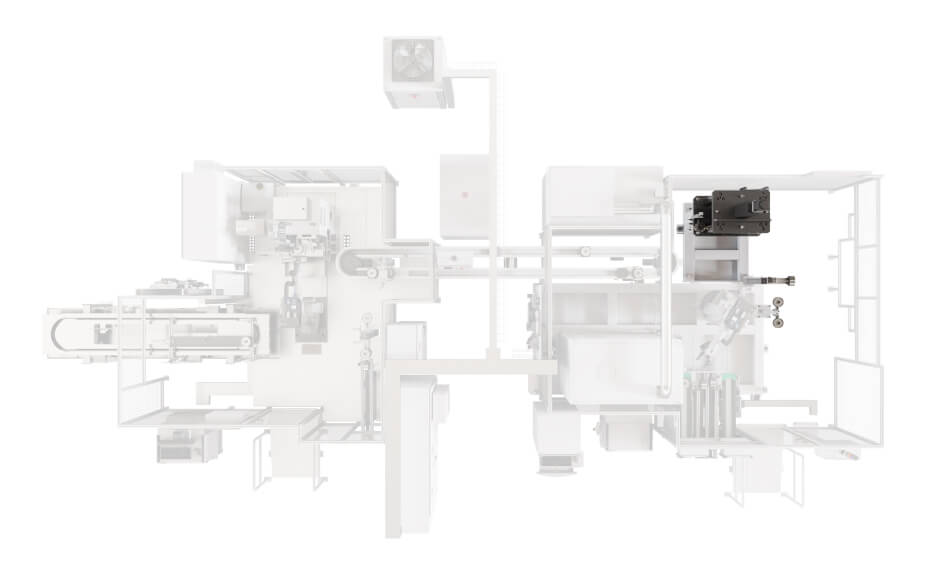

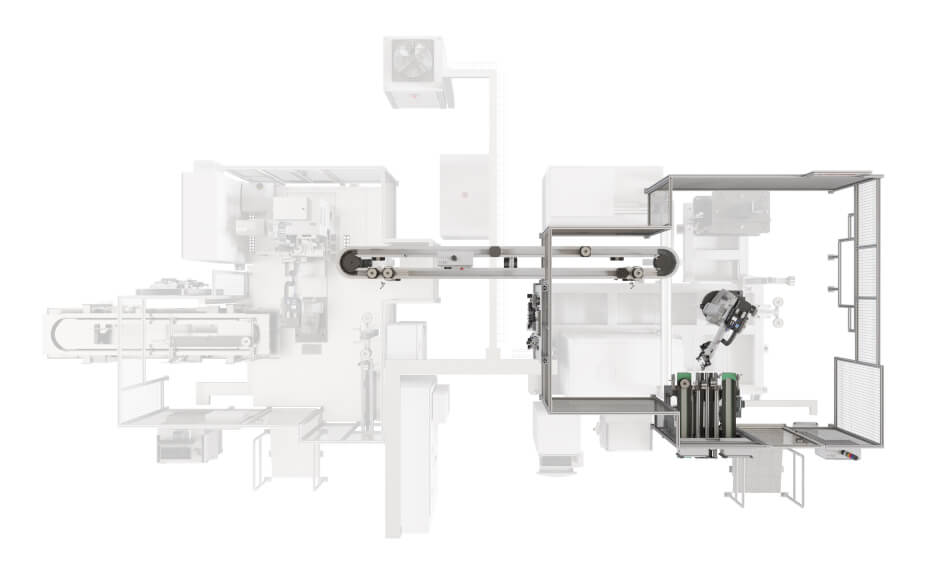

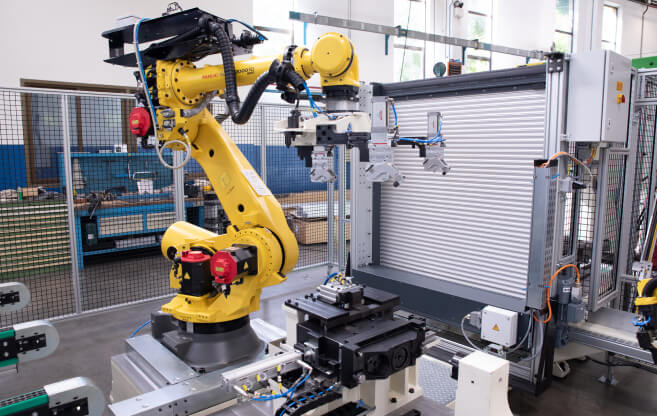

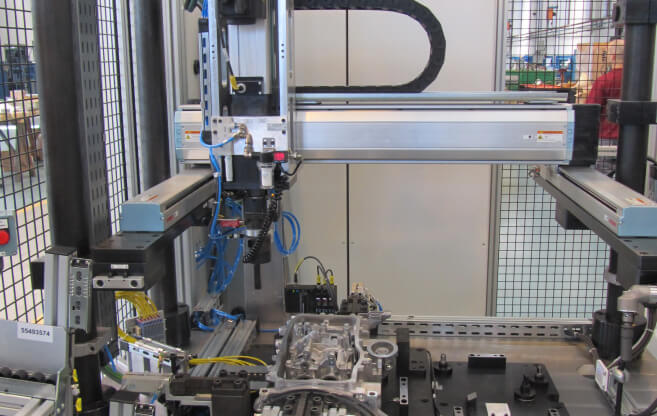

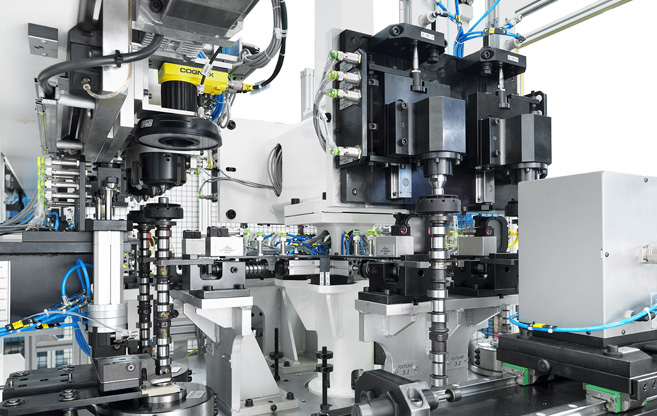

Robotized

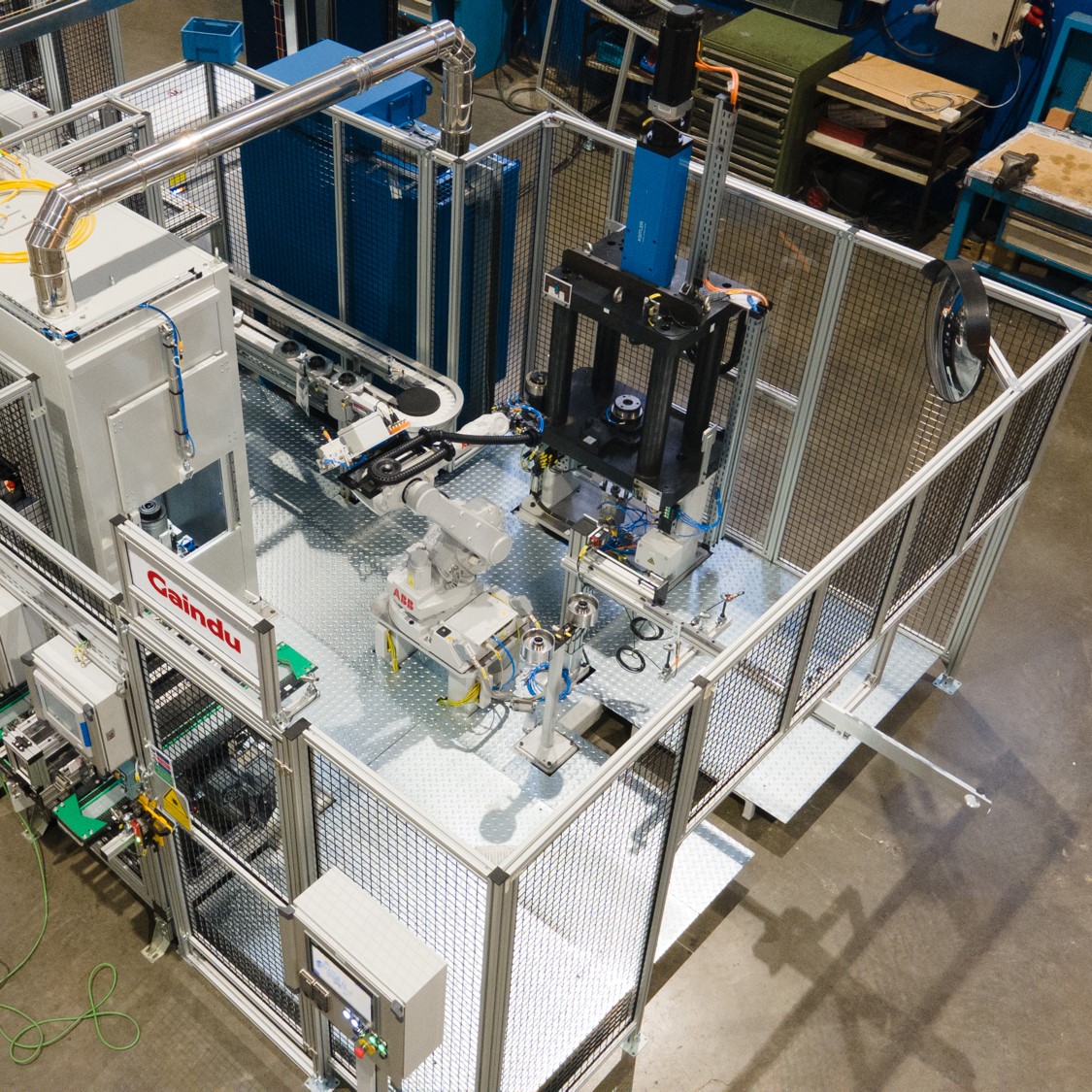

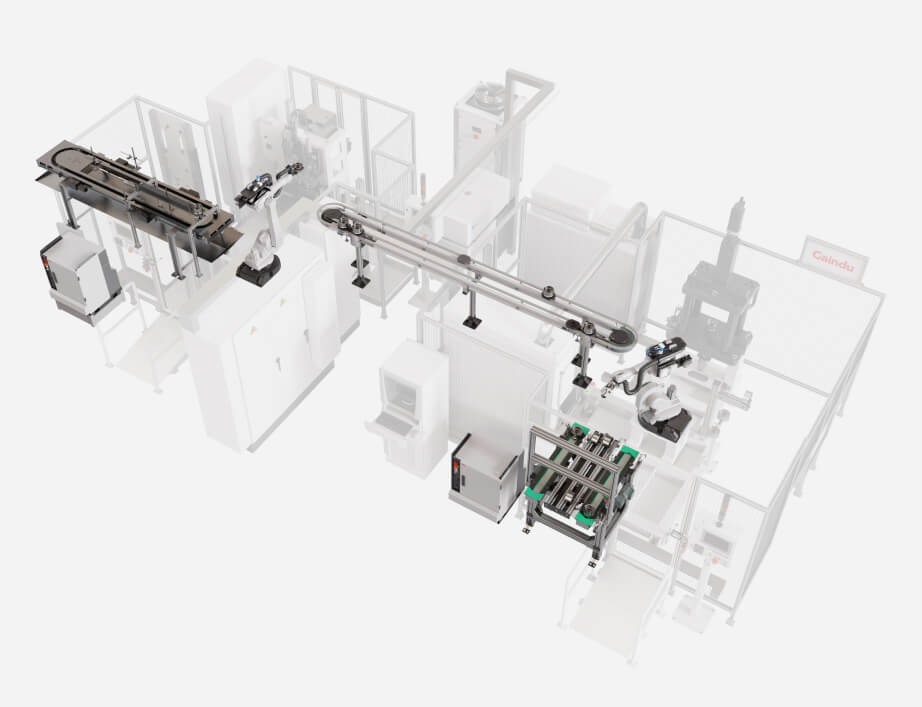

- The robot is in charge of transferring the components to the assembly station and loading the assembly to the welding station. The robotic solution provides precision and repeatability to the process.

- The flexibility provided by the robot allows the machine footprint to be adapted to the customer's needs and specifications.

- By using a robotic loading/unloading system, the high temperatures resulting from the laser welding process are not a concern and a safe unloading solution for finished parts is achieved.

Features

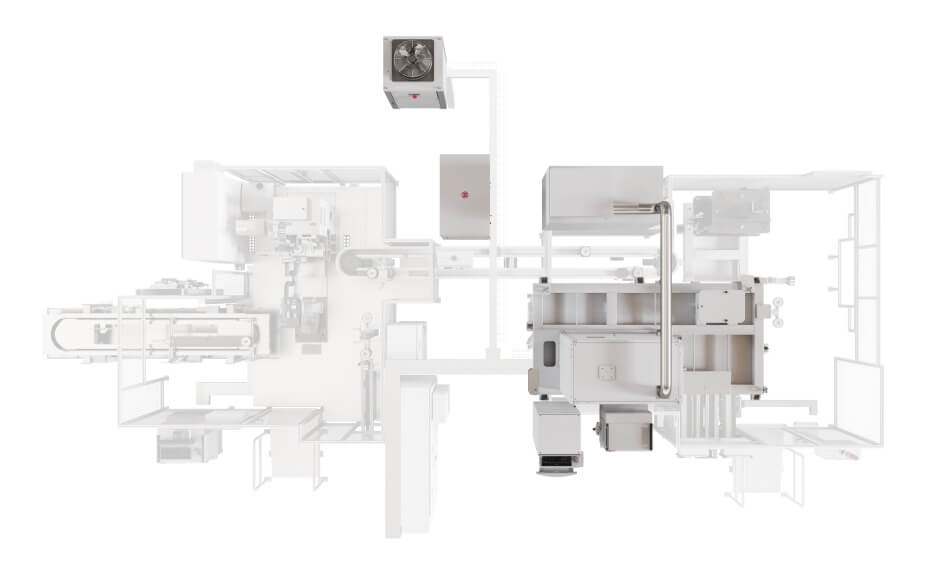

SCALABILITY

Through the gradual integration of additional technologies in the cell, there is the possibility of increasing the operations involved, adding automated processes for testing, assembly, traceability, etc...

FLEXIBILITY

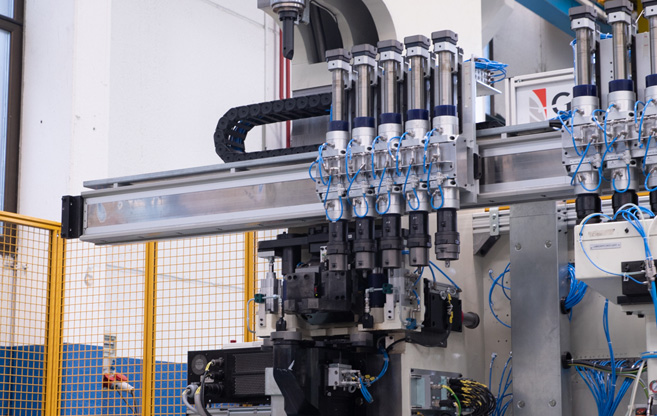

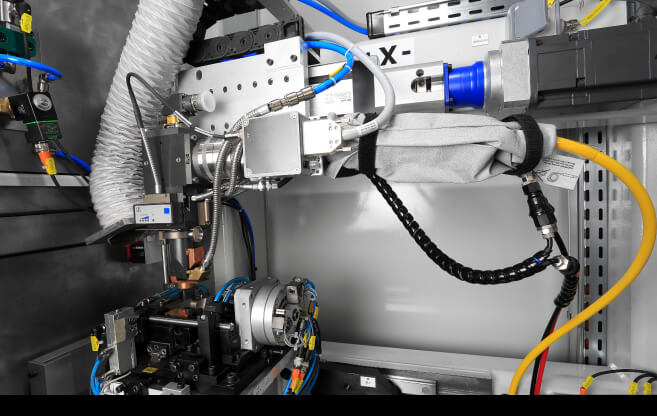

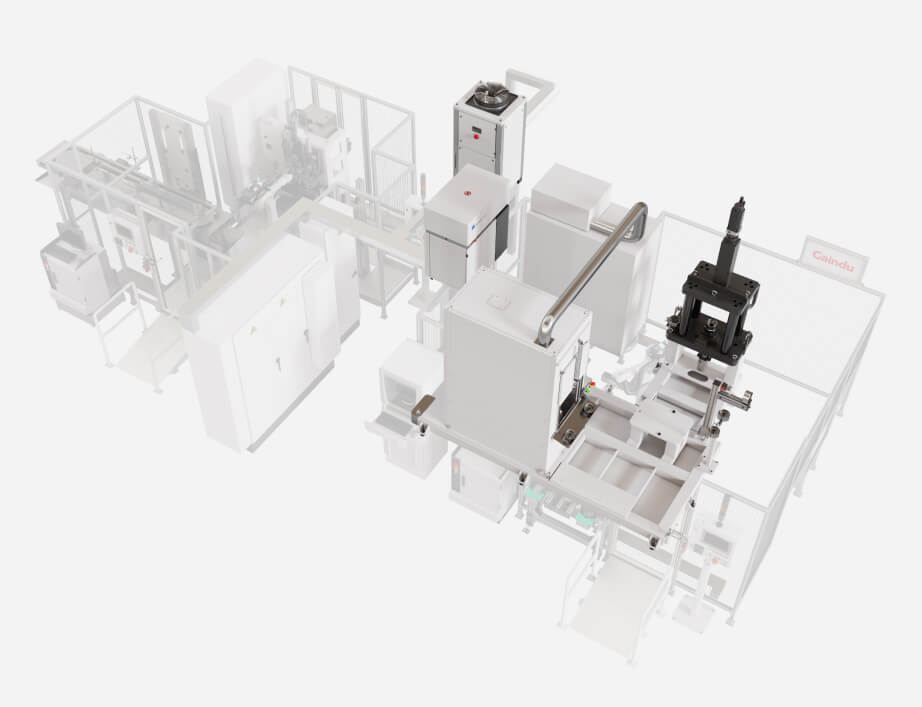

The proposed machine solution includes the possibility of moving the laser welding head on servo-controlled axes, thus obtaining a present and potential future flexibility in which to integrate new models to work in a simple way.

The machine is capable of adapting to different forms of joint between parts, varying the diameters at the time of applying the energy through the laser or achieving different geometries depending on the parts to be assembled.

Technologies

-

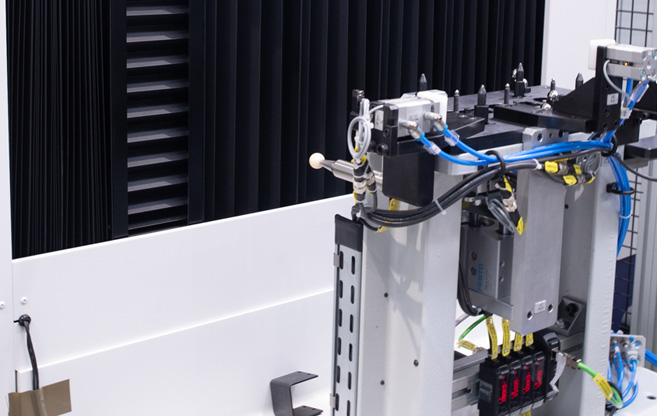

Automation Technologies

We offer integral solutions to optimize the productivity, being the automation of the loading/unloading and feeding of parts to the production systems a fundamental part of this process.

-

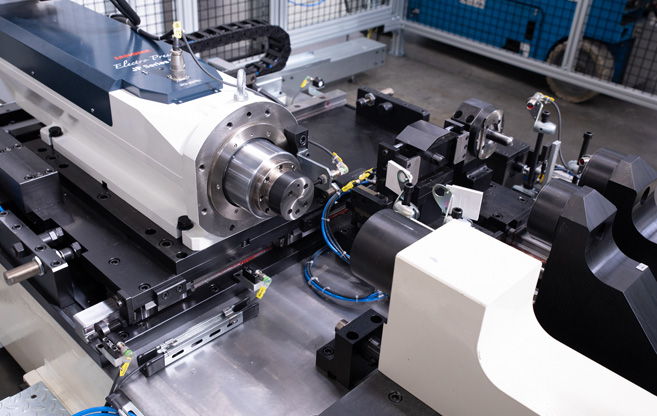

Assembly Technologies

After more than forty years of collaboration with the best manufacturers in the world in order to integrate the most advanced assembly systems in our installations, we are able to offer comprehensive solutions for the assembly and joining of components under the use of diverse technologies.

-

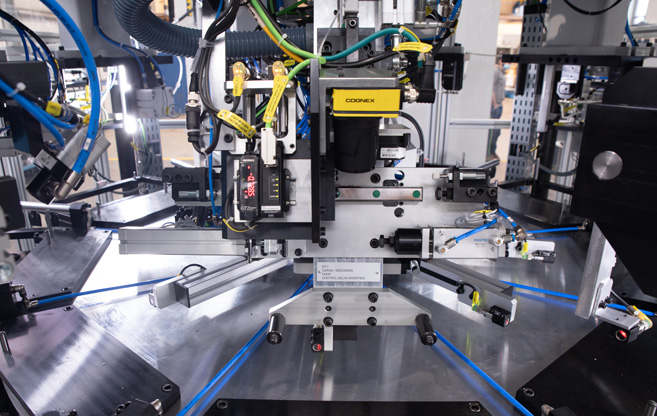

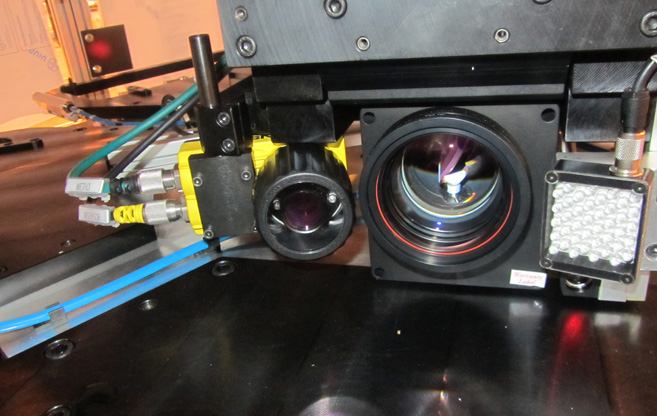

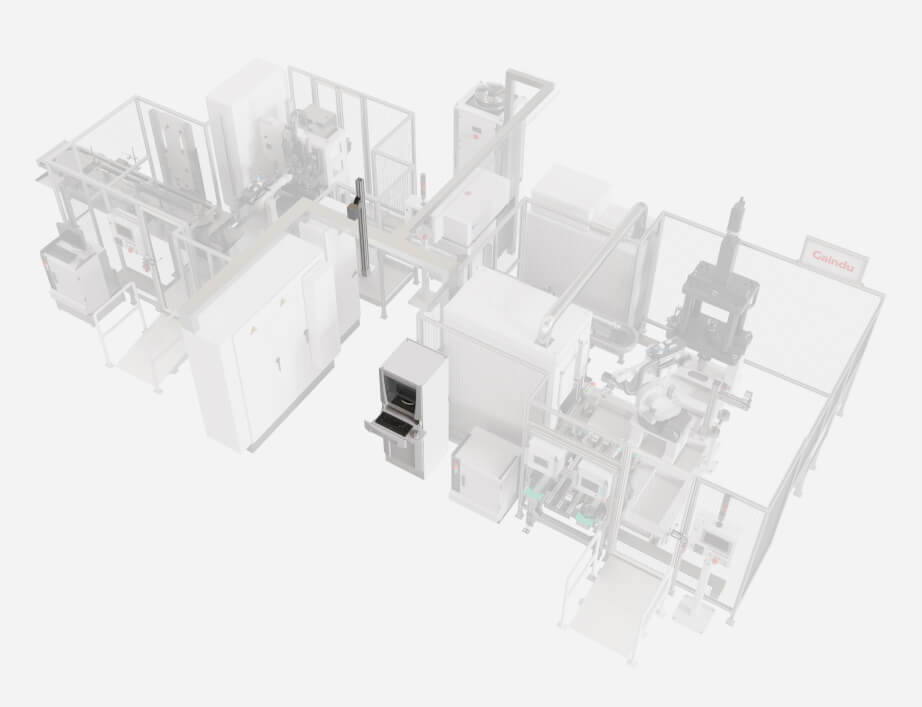

Traceability Technologies

Our cells include the means to completely trace the parts and ensure that the information is recorded for further processing. Some of the technologies used for this purpose include marking, reading and data storage.

-

Testing Technologies

Quality assurance in our products and therefore in our customer's final product is an absolute priority for us. In this direction we work to offer the best quality control systems in different areas.

Conveyor

Robot

Feeding

Conveyor

Robot

Feeding

Pressing

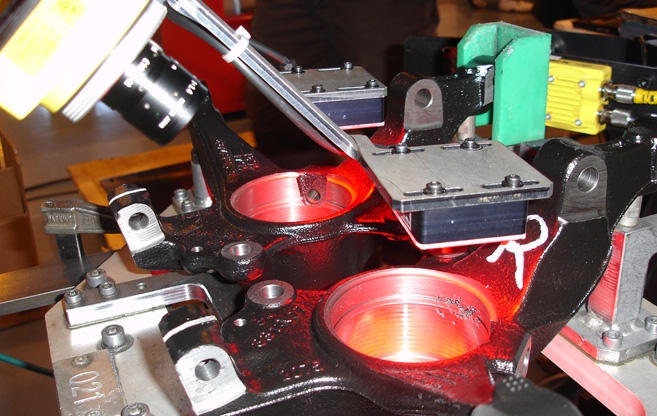

Laser Welding

Pressing

Laser Welding

Reading

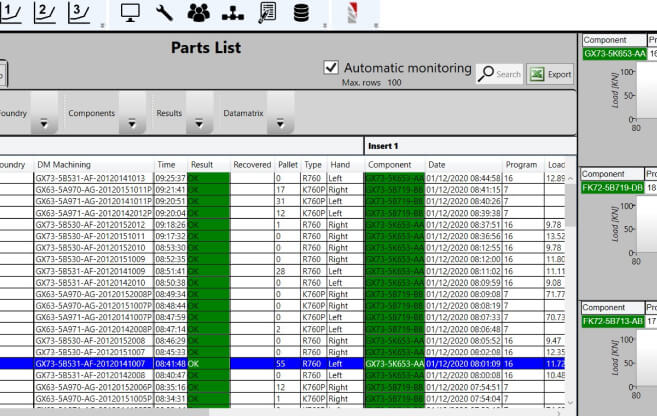

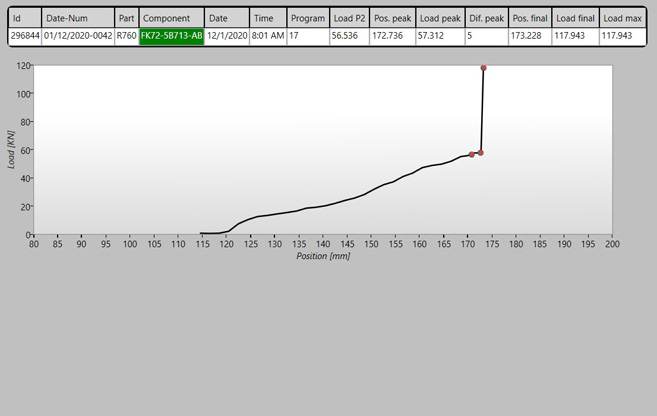

Gaindu Tracker

Industry 4.0

Reading

Gaindu Tracker

Industry 4.0

Ultrasonic

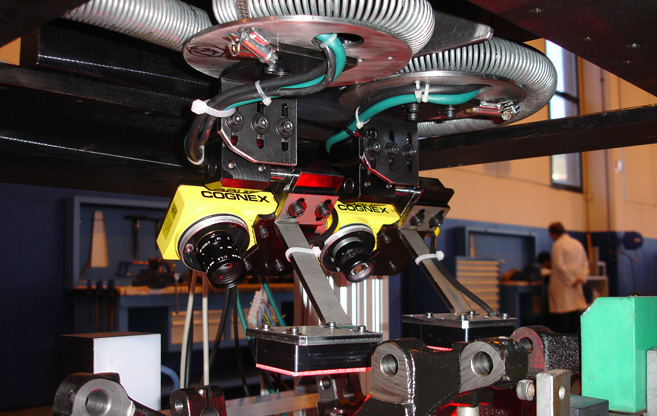

Vision

Post-process Measuring

Ultrasonic

Vision

Post-process Measuring

Applications

-

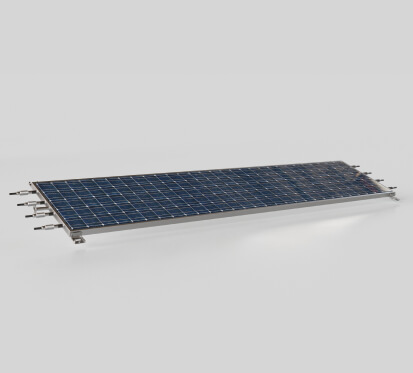

PHOTOVOLTAIC PANEL

-

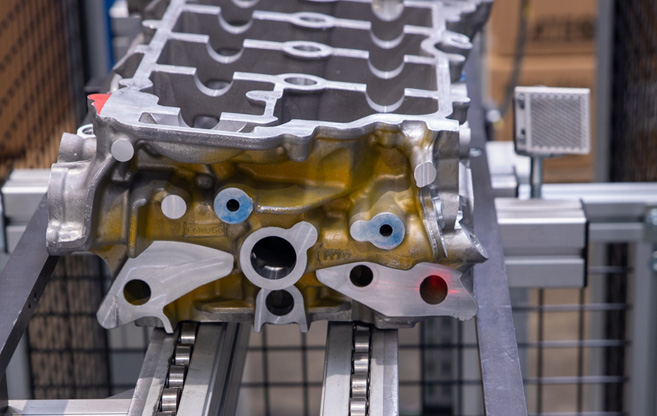

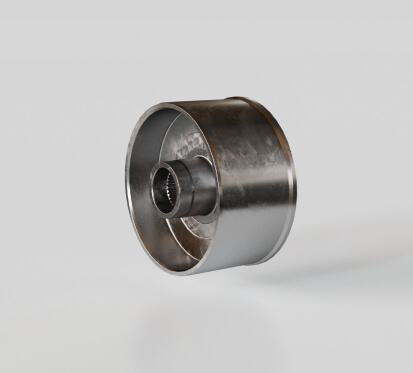

TRANSMISSION SHAFT

-

TRANSMISSION SHAFT

-

PINION

-

ROTOR SHAFT

Case studies

Gaindu has collaborated to improve their production processes or undertake complex operations in an efficient way.

MORE ABOUT CASE STUDIESInterested in knowing more how we can help you?

CONTACT US