Assembly Technologies

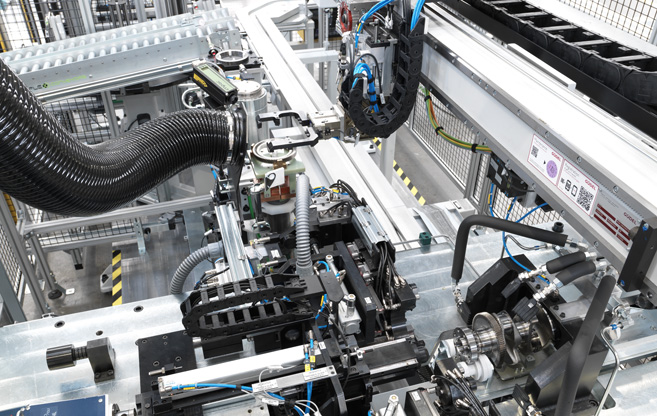

After more than forty years of collaboration with the best manufacturers in the world in order to integrate the most advanced assembly systems in our installations, we are able to offer comprehensive solutions for the assembly and joining of components under the use of diverse technologies.

Integrated technologies

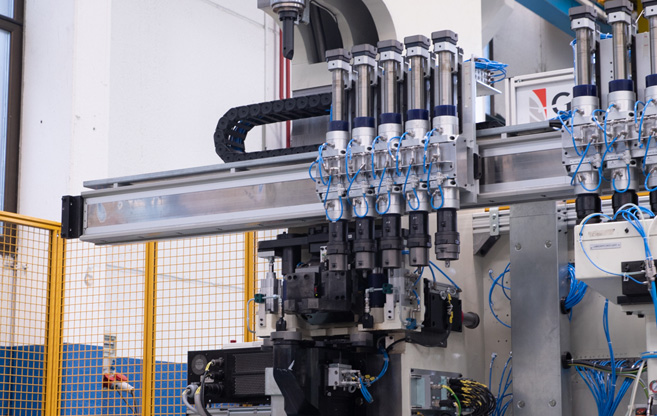

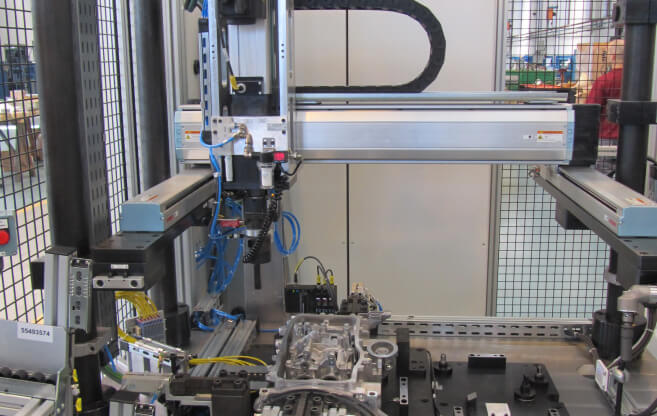

Tightening

- Possibility to perform tightening operations using electrical screwdrivers, controlling the applied torque and final angle on the process.

- Simpler tightening / untightening operations could also include pneumatically driven tighteners or tailor made untightening electromechanical units.

- We adapt our assembly solutions to our customer's need, integrating on that purpose their preferred electrical screwdriver brand.

- Union of components using all type and sizes of bolts, screws, thread plugs, etc…

TRADEMARKS

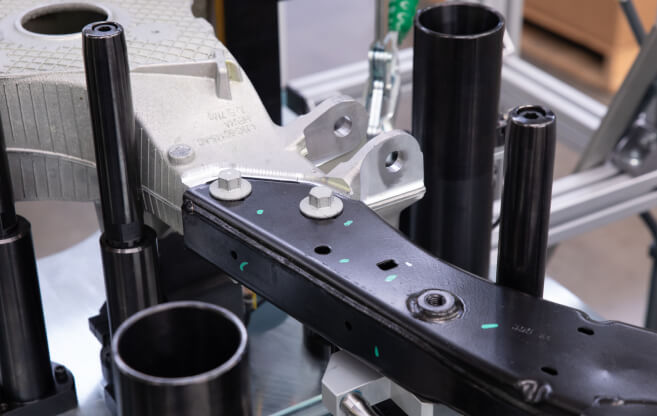

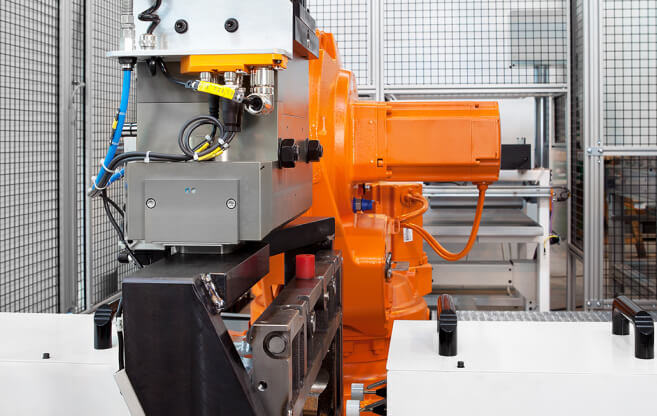

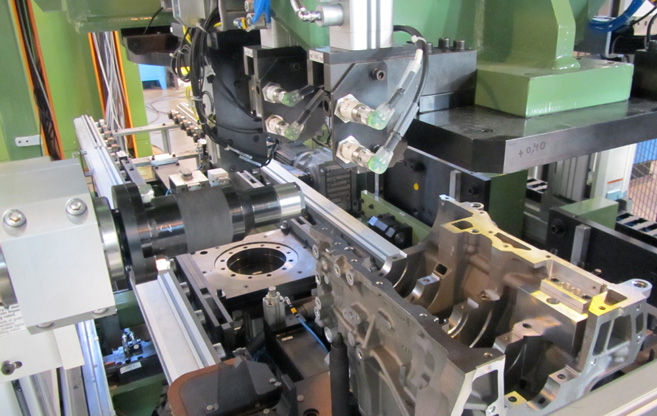

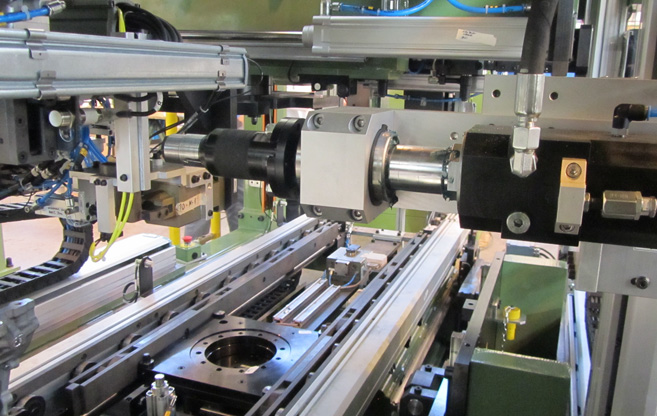

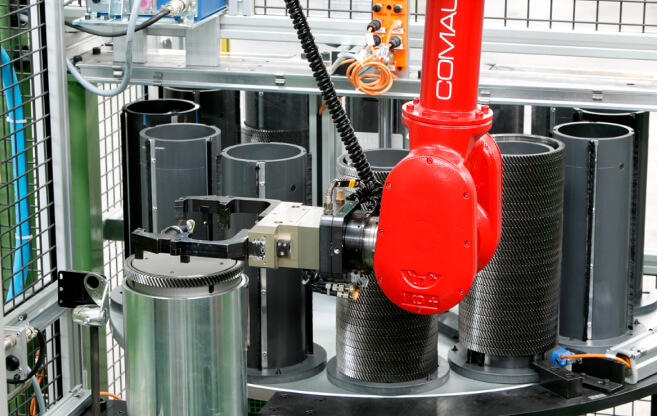

Pressing

- Monitoring of the assembly processes for component pressing, controlling the parameters during the whole cycle.

- At Gaindu we have installed more than 300 electric presses with which we have assembled all types of parts and units. Assembly processing of engines, suspensions, gearboxes, etc...

- We are the official distributor of JANOME electric presses in Spain, having collaborated with them directly in the validation and expansion of assembly processes using electric presses.

- Following our vocation of customer-oriented solutions, we adapt to the approved brands and preferences of our customers when designing our installations. This has led us to work with the leading global manufacturers of electrical presses and gives us the advantage of being able to offer our solutions integrating reliably any of these brands.

TRADEMARKS

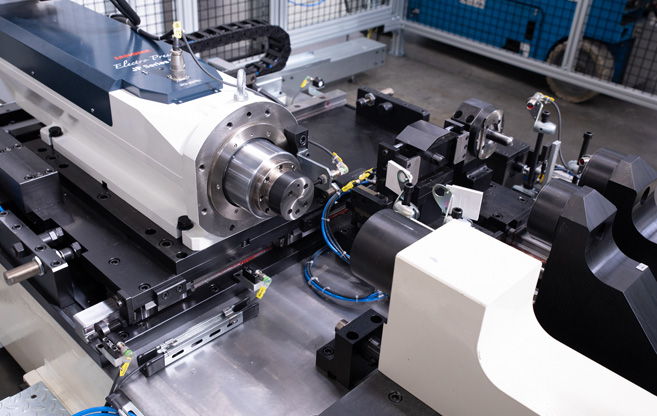

Measuring

- Possibility of complementing the assemblies by in-process measurements, to guarantee variable dimensions depending on the actual part.

- Measuring systems through integration of third-party equipment or in-house systems using market-standard measuring probes

- We use the measurement units to, for example, generate reference pressing dimensions based on the values obtained, in order to guarantee 100% of the parts.

- When integrating a gauging system, we always include the means for system calibration, either by manual procedures or integrated into the automated system.

TRADEMARKS

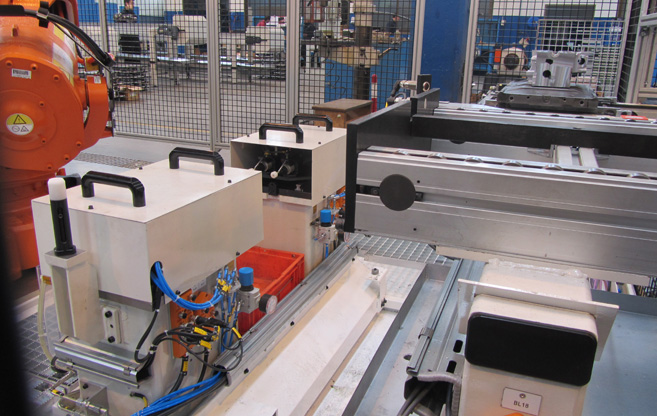

Lubrication

- Some assembly processes, especially pressings, require a prior application of lubricant to assist during assembly.

- At Gaindu we have large experience integrating different types of lubrication prior to assembly, using various systems and materials depending on the needs of our customers.

- Lubrication of components or housings, by means of greases or oils of various viscosities. Possibility of additional control by vision of the correct dosing or the quantity of lubrication provided.

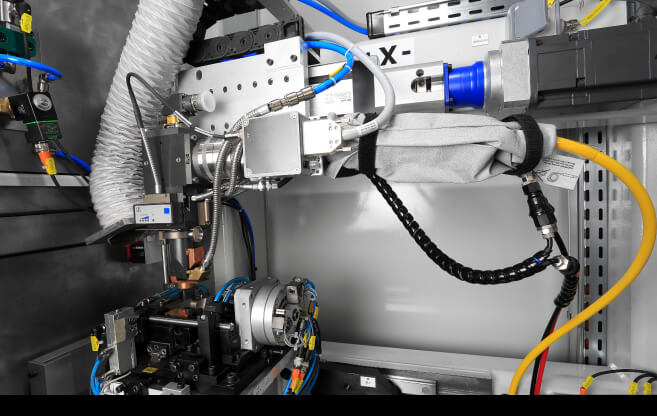

Laser Welding

- Laser welding technology has become a priority in industrial sectors where the aim is to obtain assemblies with very tight tolerances.

- We have been collaborating for years side by side with the main laser equipment manufacturers, thus providing our machines with the latest and most advanced solutions available in the market.

- There are several laser welding alternatives using different technologies: Fiber, CO2, disc, diode…

- In Gaindu the safety of our facilities is an unquestionable feature, so all our laser welding machines have the appropriate protections to ensure the safety of our customers.

TRADEMARKS

Riveting

- Within the assembly operations we perform at Gaindu, riveting is one of the technologies used for joining various components. There are multiple riveting applications in the market, with different models of rivets depending on the type of joints, materials, etc...

- At Gaindu we have experience in the integration of both manual and automatic riveting equipment, in which we often integrate automatic feeding of the components and the necessary automation of the process to provide it with the necessary control tools.

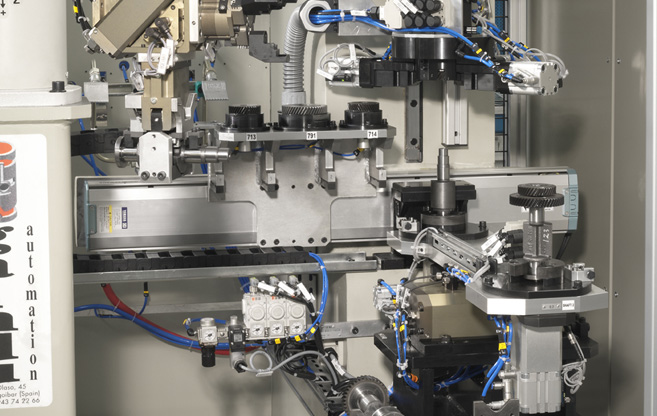

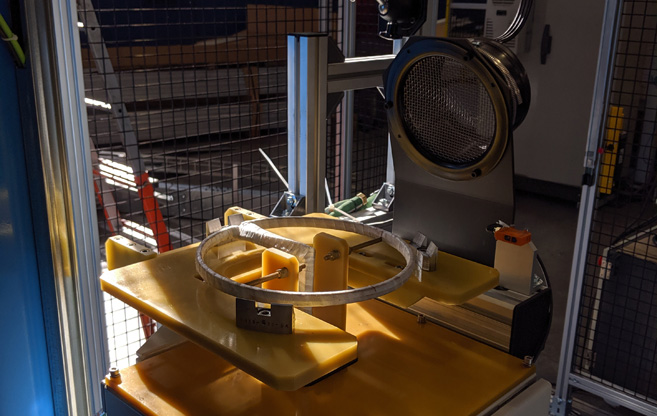

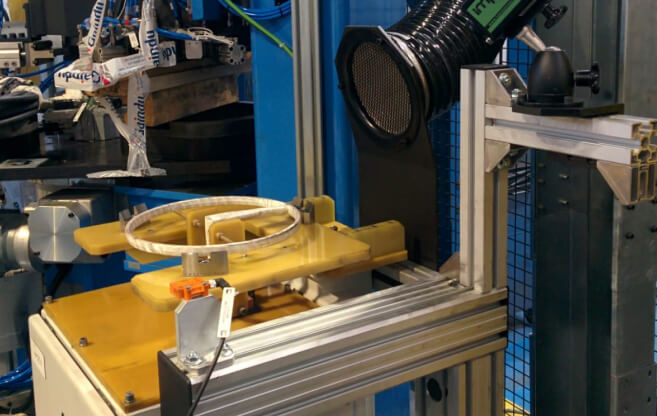

Induction

- In some cases where components are pressed on shafts, it is necessary to expand the inside diameter of the part to be assembled or the inside diameter of the housing on which the component is pressed prior to the insertion operation.

- For this purpose, Gaindu performs pressing applications in which we include a previous operation of induction heating, thus reducing the interferences between the parts to be joined and optimizing the forces required during the process.

- Induction heating processes are carried out integrated in our automated machines, where we control the temperature reached in the parts through the use of optical pyrometers. In order to evacuate the fumes generated during the heating process, we operate with suction filtering equipment installed in the heating stations.

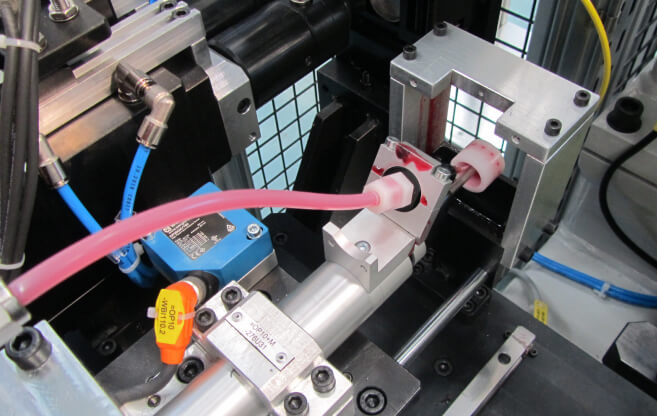

Glue dosing

- In component assembly and joining technologies, there are applications in which a previous application of adhesive is necessary to guarantee the correct sealing of the components once they are pressed.

- In our systems we integrate adhesive dispensing equipment of different types, with different viscosities and curing times. We also integrate control systems for correct dosing, with vision systems or chromatic sensors.

Interested in knowing more how we can help you?

CONTACT US