Traceability Technologies

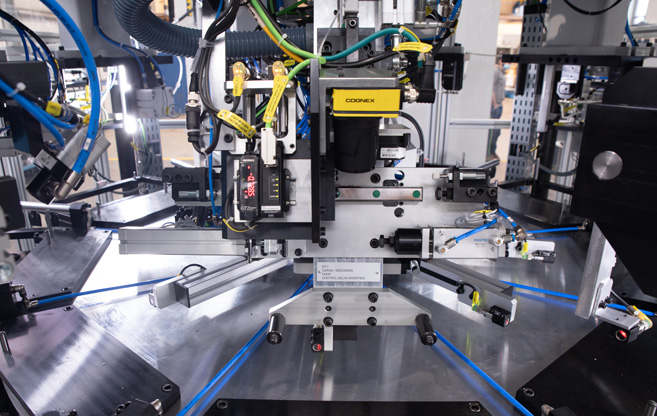

Our cells include the means to completely trace the parts and ensure that the information is recorded for further processing. Some of the technologies used for this purpose include marking, reading and data storage.

Integrated technologies

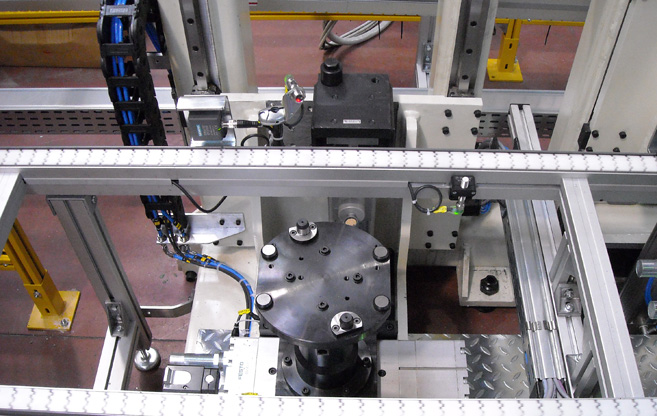

Reading

- Within the operations related to traceability, and especially after marking the parts on the machine, it is necessary to check the correct marking or to incorporate the unique part ID to associate the process data to the part.

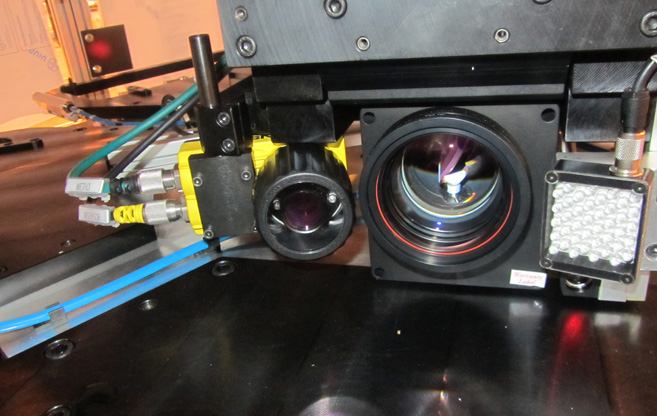

- Integration of cameras or sensors for 2DM code / QR / Barcode reading.

- Possibility of marking degree evaluation according to the ISO/IEC TR 29158 (AIM DPM-1-2006) standard, by means of special verification units.

TRADEMARKS

Industry 4.0

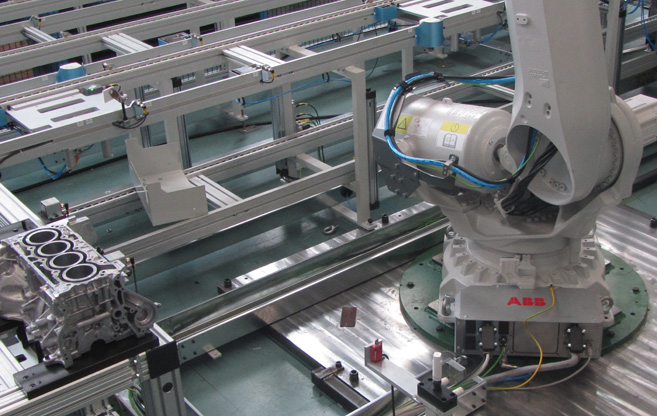

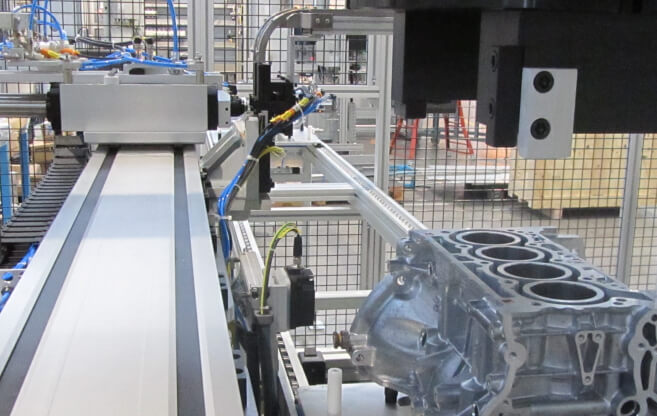

Gaindu has put considerable effort into the standardization of control systems, for the automatic collection and analysis of relevant data from production systems, classified into the following areas:

- Piloting, making it possible to configure/detect production sequences and formulas for the various types of parts.

- Status, providing information on machine availability and utilization, allowing to analyze productivity, detecting bottlenecks and improvement actions.

- Process, associating to the part identifier the data of the different processes performed on it. The identification of the main parts and their components is done by means of identification techniques such as reading the 2DM code marked on them or reading the RFID cards located on them or on their transport elements.

- Automation, recording the detections, movements and actuations performed by the machines, which allows to detect points of improvement in performance and to perform preventive maintenance of its components.

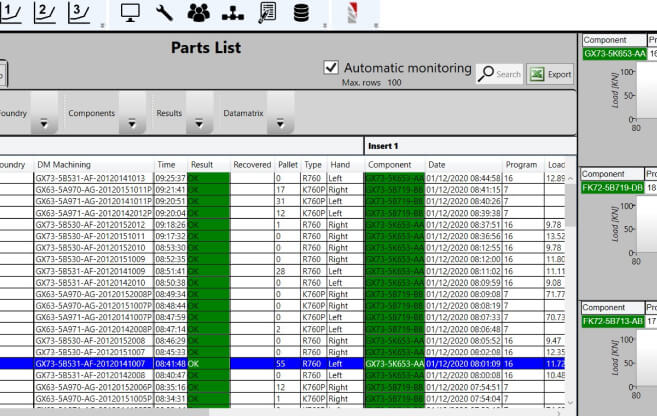

Gaindu Tracker

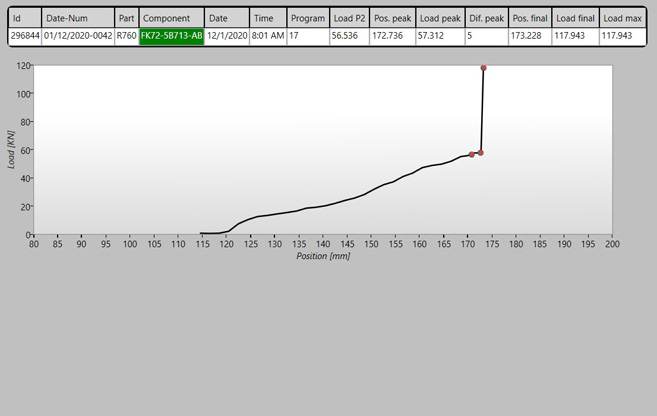

In order to respond to the traceability needs of our customers, at Gaindu we have developed our own software called Gaindu Tracker, with which we provide our installations with the functionality to record process data associated with unique part IDs.

We integrate industrial PCs from leading manufacturers as hardware support for our customized software development.

Complete collecting of data related to the process:

- Leak test values

- Insertion forces and positions

- Torque and anglel values

- Etc.

We study each project in detail in order to adapt to the existing IT systems in our customers' plants, integrating our machines in their information networks.

Marking

- Within the traceability strategy of the parts produced, their marking is a fundamental step. The marked data uniquely identifies each part and allows the association of process data for future use if necessary.

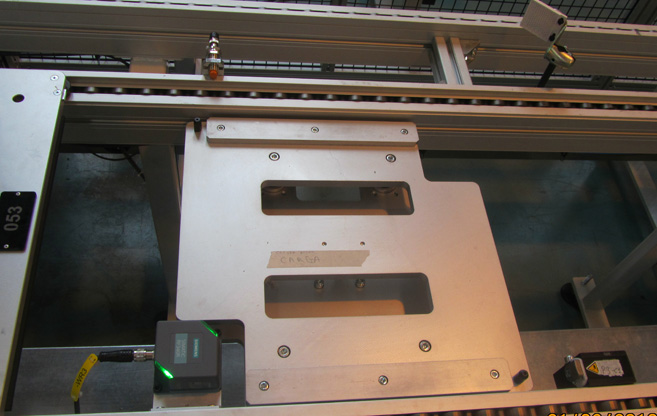

- We design, manufacture and integrate marking units to etch 2DM / Barcode / QR codes, among others.

- There are several marking alternatives using different technologies: laser marking, micro-percussion or impact marking.

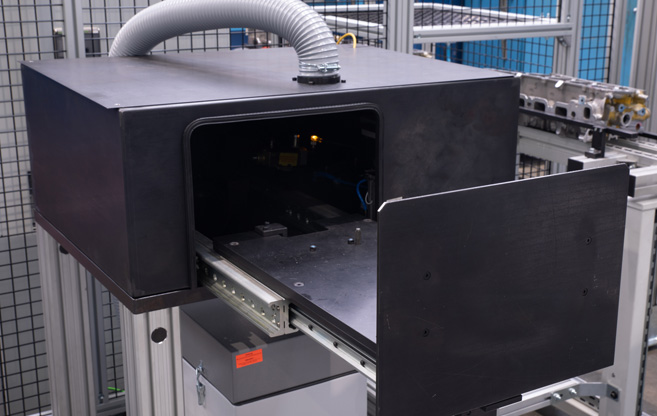

- At Gaindu we design laser marking stations in which we prioritize safety by means of enclosures compatible with Class 4 lasers.

- Due to the experience gained over decades, we are able to integrate the main brands of laser manufacturers in the market or other brands required by our customers.

TRADEMARKS

RFID

- As an alternative or complement to part marking, RFID tags are used in traceability systems on which process data can be written/read.

- RFID tags are mounted directly on the part to be produced (when possible) or on transport pallets attached to them.

- With the combination of tags on parts and readers/writers present on the line's machines, the information is stored so that it can be associated with the part and transferred to an information system or included in a subsequent marking of the part.

TRADEMARKS

Labelling

- When it comes to fully complete our turnkey installations, Gaindu offers the possibility of integrating the final labeling of the finished parts, including the relevant process information defined by the customer.

- The labeling options for parts, pallets, or packaging are done by automatic labeling equipment or manual printers in which an operator applies the tag during the final inspection of the part before packaging.

- The generation of the barcodes or 2DM codes on the label is managed by Gaindu’s own traceability system, Gaindu Tracker, which communicates with the printing equipment to transfer the necessary data to be reflected on the corresponding sticker.

Interested in knowing more how we can help you?

CONTACT US