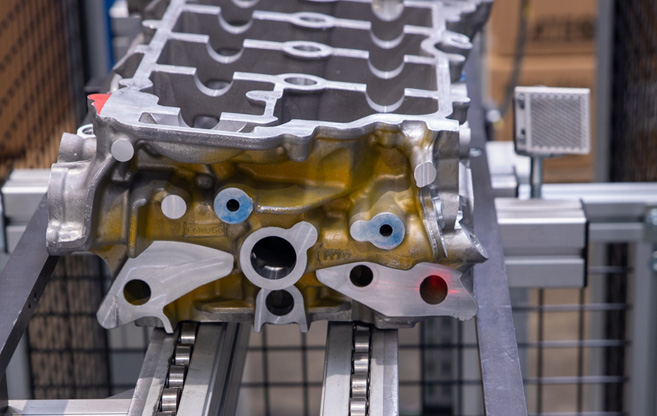

Connecting rod cracking

Connecting rods fracture process guarantees a practically imperceptible re-joining of the components, achieving much higher levels of precision, quality and efficient use of materials

Our Solutions

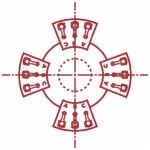

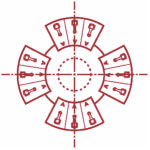

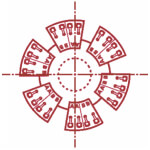

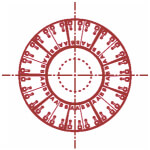

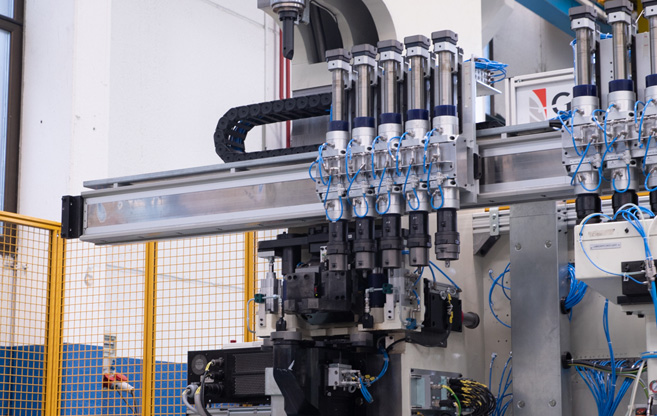

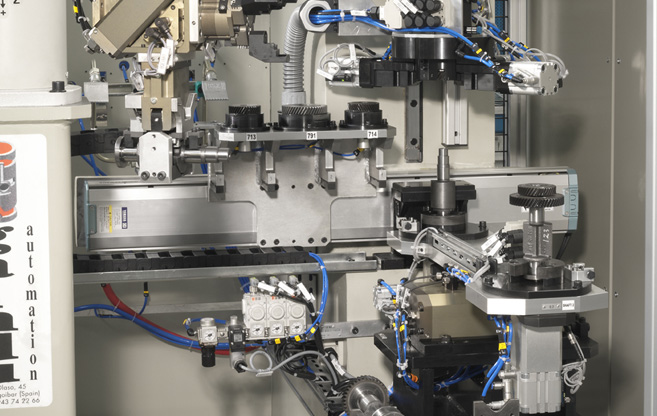

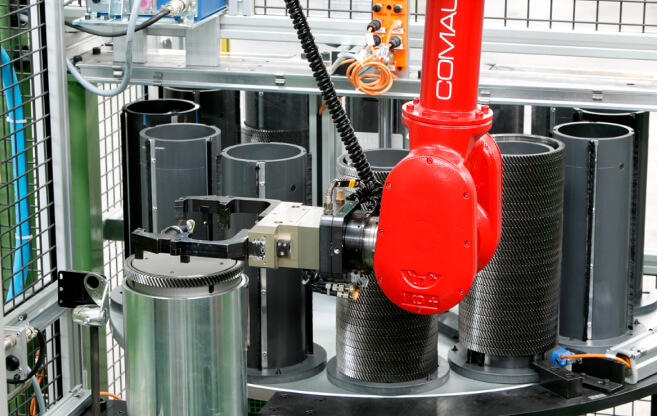

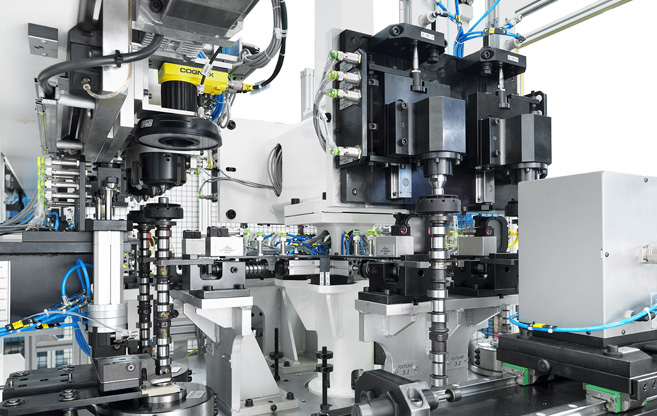

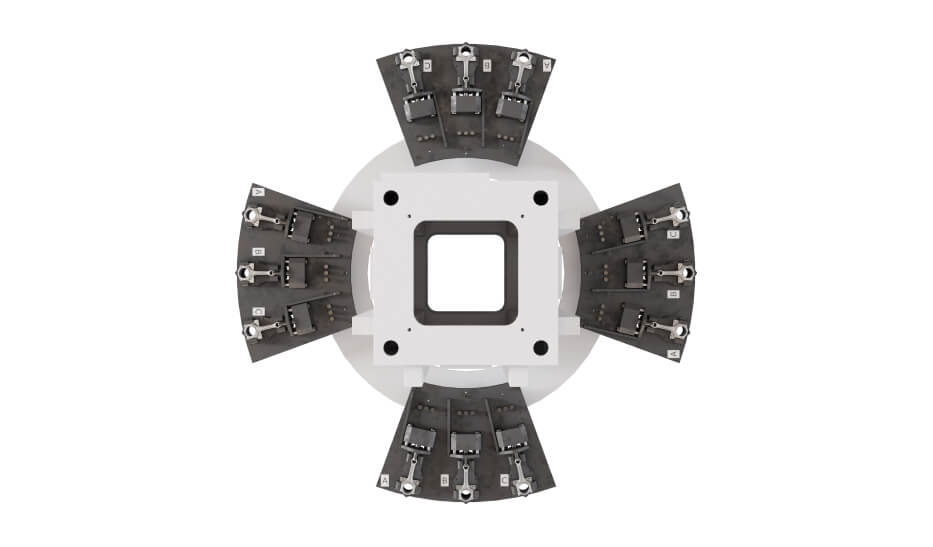

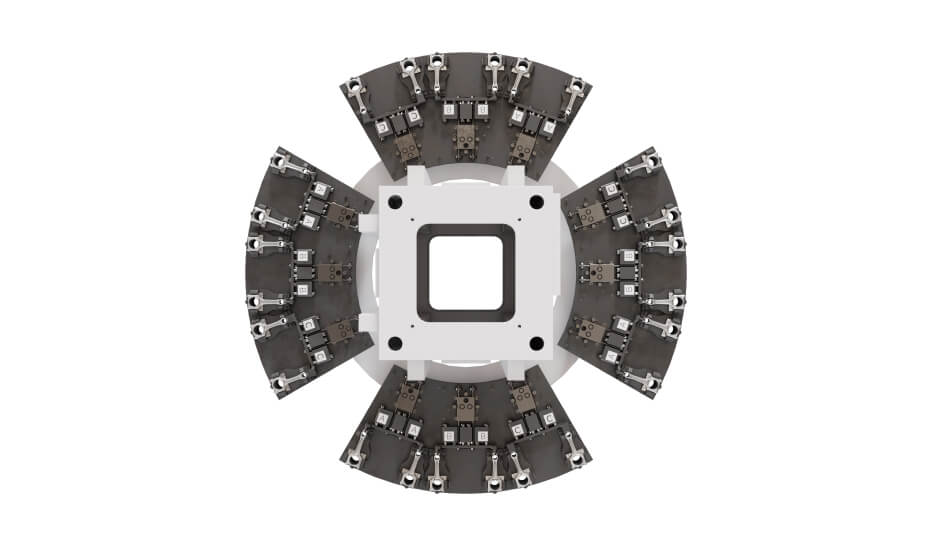

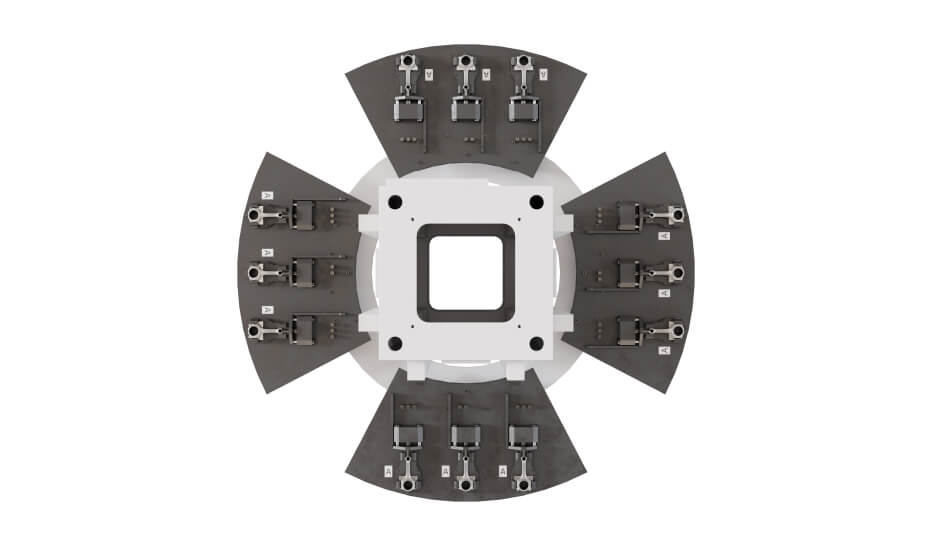

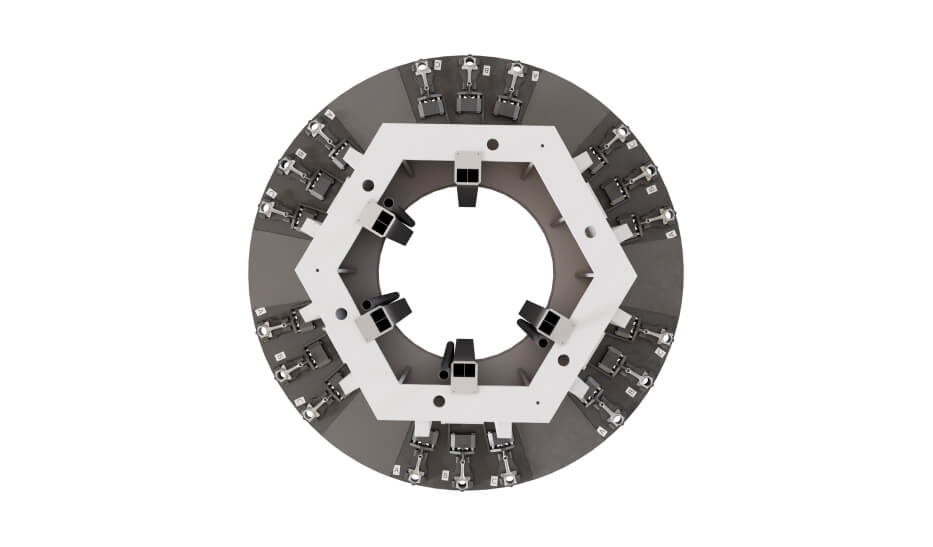

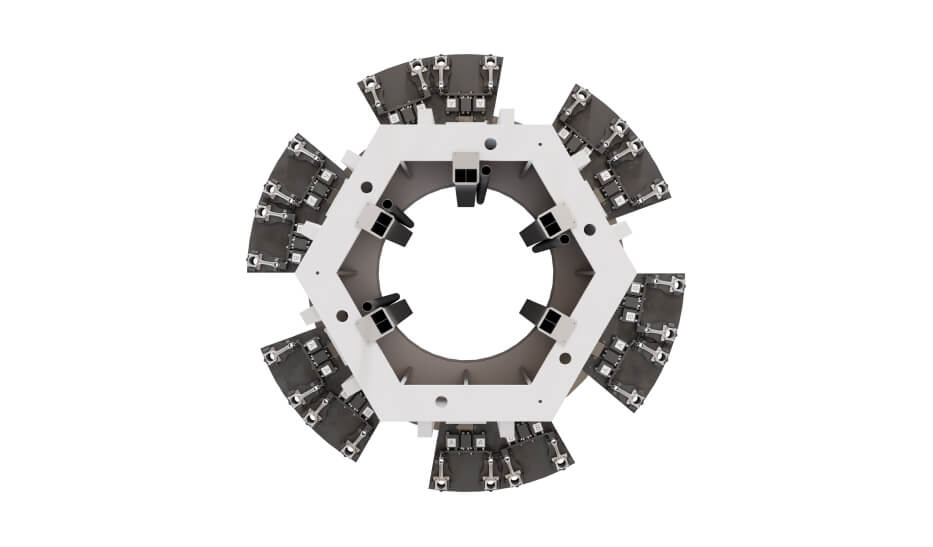

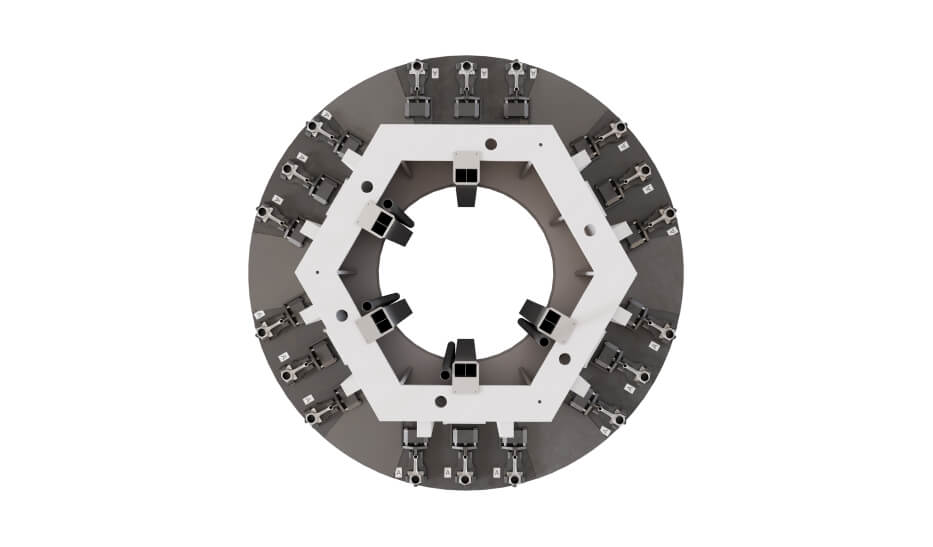

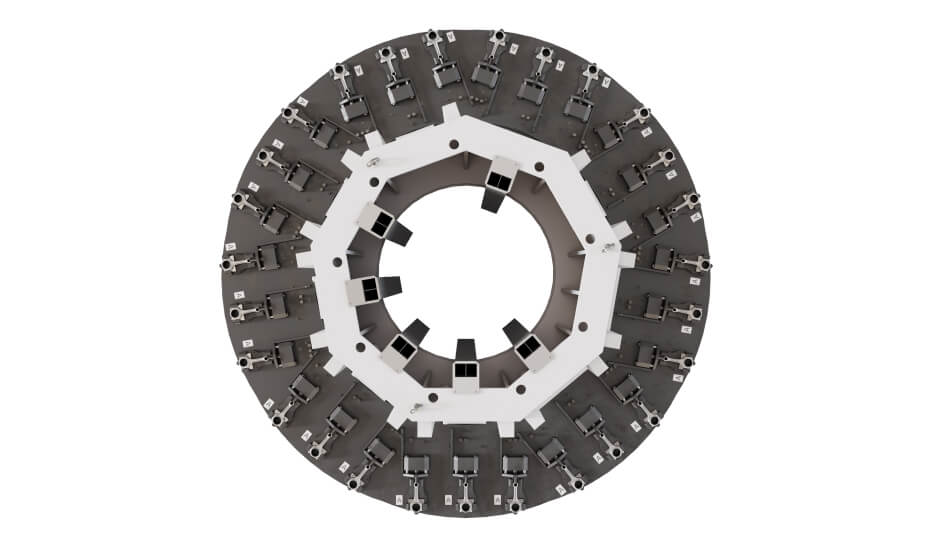

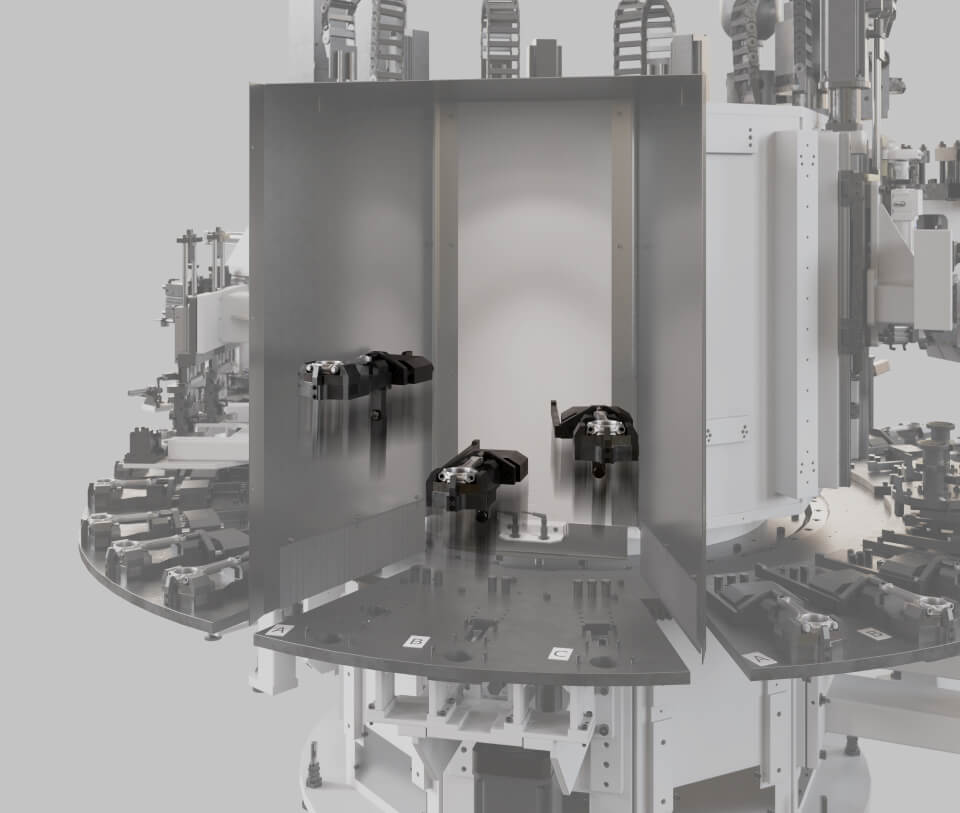

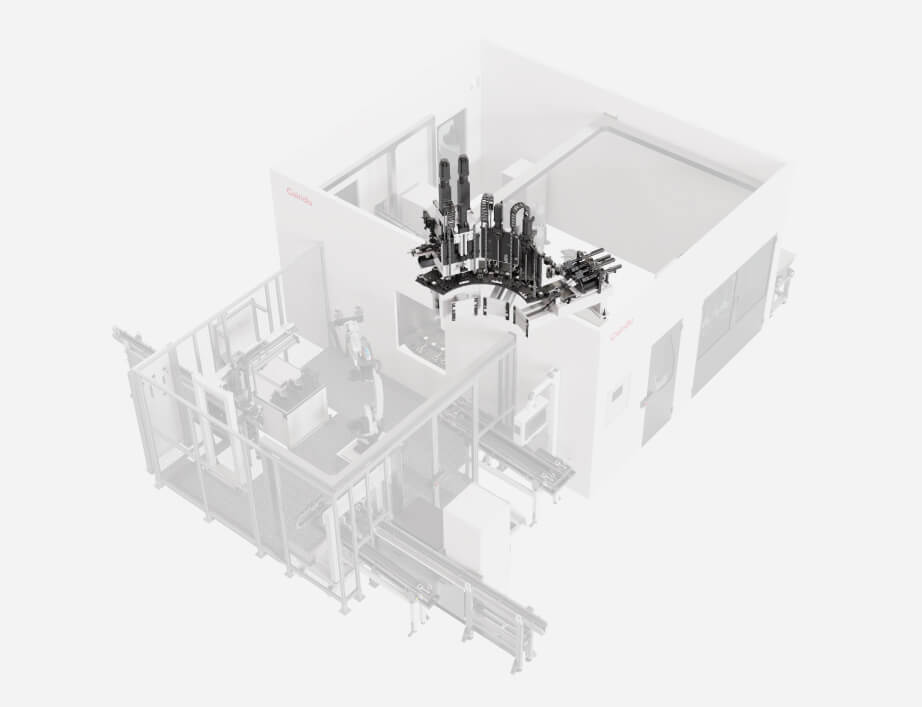

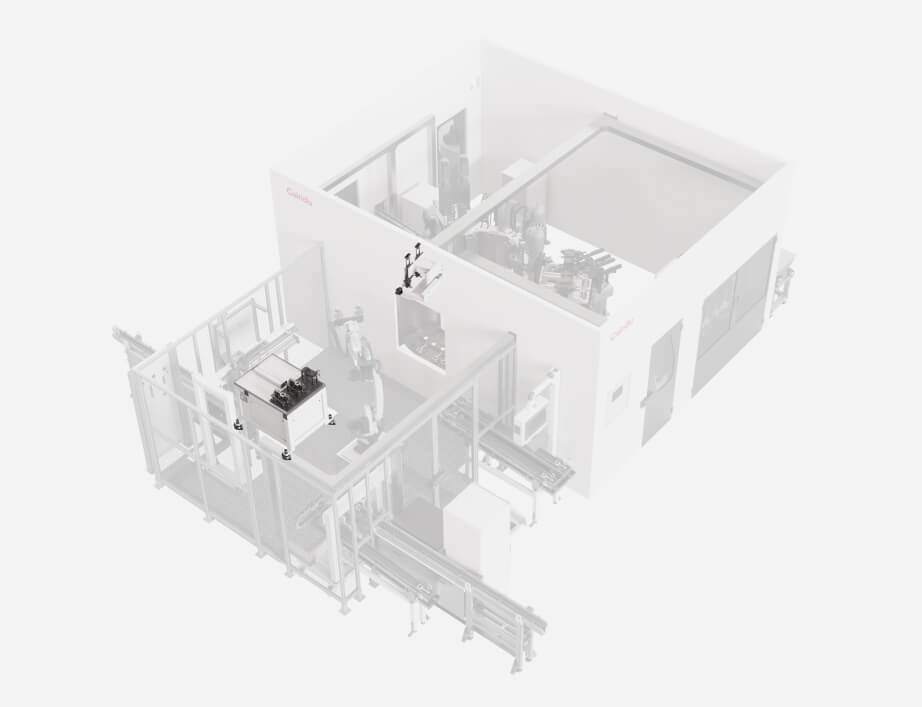

We work to offer a standard machine solution capable of adapting to different production scenarios, flexible for different types of connecting rods and integrating the necessary additional control processes. Our proposal is based on a rotary transfer machine solution configurable regarding stations and number of parts to be worked simultaneously.

-

Rotary

- Circular transfer machine solution adaptable for low, medium or very high production outputs

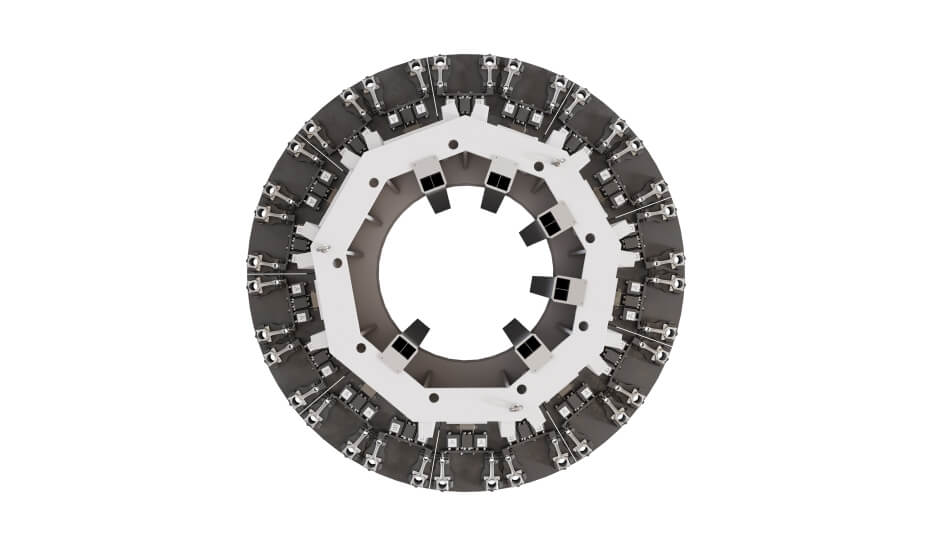

- Developed under the premise of providing high flexibility to our customers, with the ability to work with several references with minimal changeover times between models.

- Machine designed under Gaindu's philosophy of robustness and durability, to guarantee optimal performance and quality assurance not only in the short term but also in the long term.

- Configurable in the number of stations, amount of transfer tools as well as different optional operations. Integration of all peripherals for complete automation (robot, conveyors, measuring equipment...).

Features

MODULARITY

Machine configurations available depending on required production and diversity

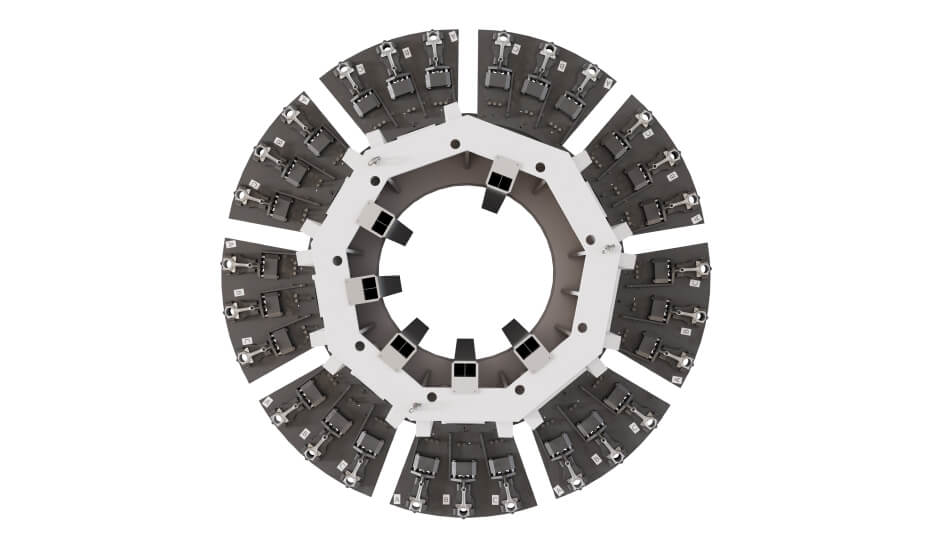

FLEXIBILITY

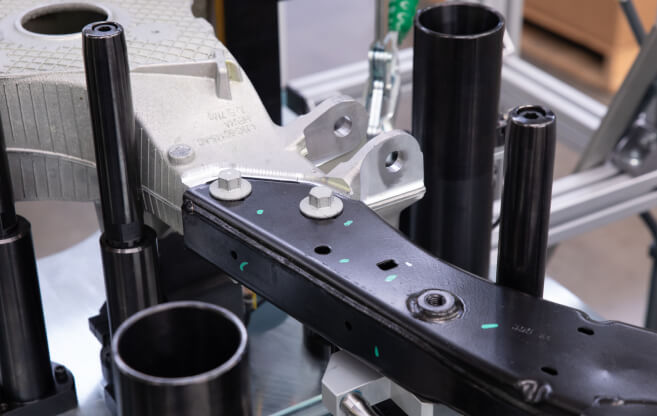

The design of the transfer bases allows the pre-arrangement of up to 3 reference tooling models mounted at the same time.

For greater flexibility, each of the reference tools can be replaced by one operator in a simple operation of very short duration. This functionality triggers the options of integrating additional connecting rod models at present or in the future.

The same machine serves as a configurable basis for connecting rods with different characteristics:

- Flexibility in sizes and geometries

- Flexibility in crank bore - pin bore pitch

- Flexibility in screw hole pitch

- Possibility to assemble cylindrical, conical or other shaped bushings

Technologies

-

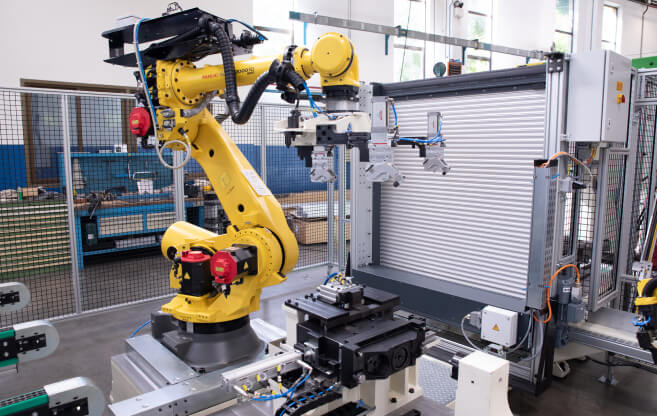

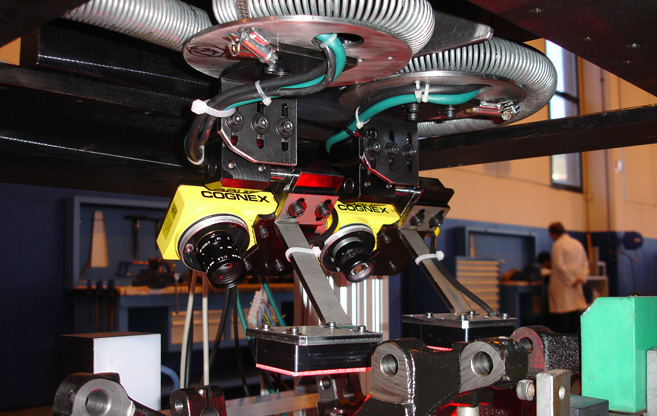

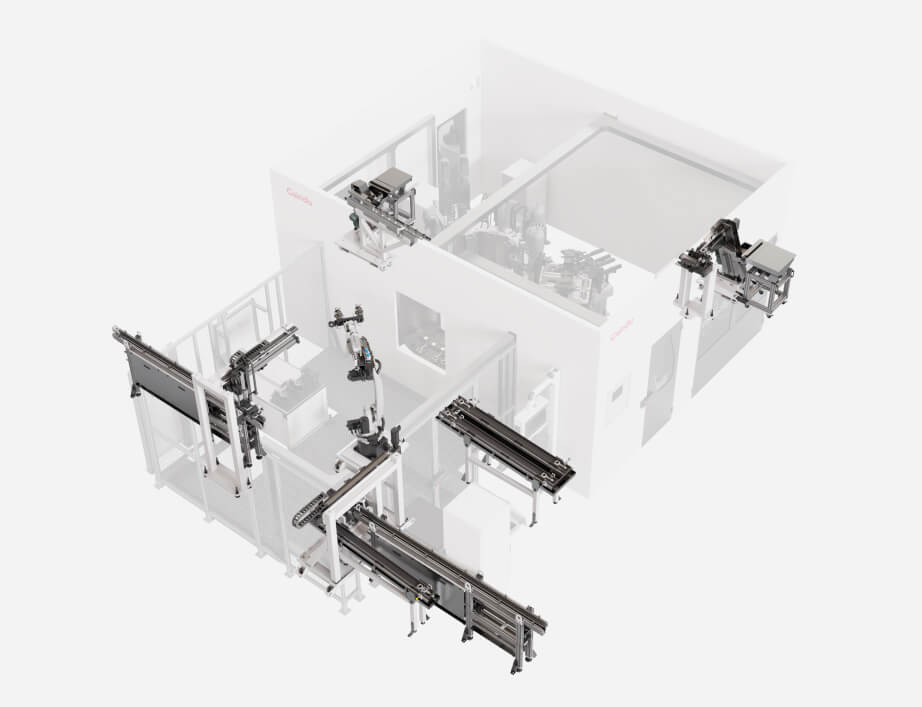

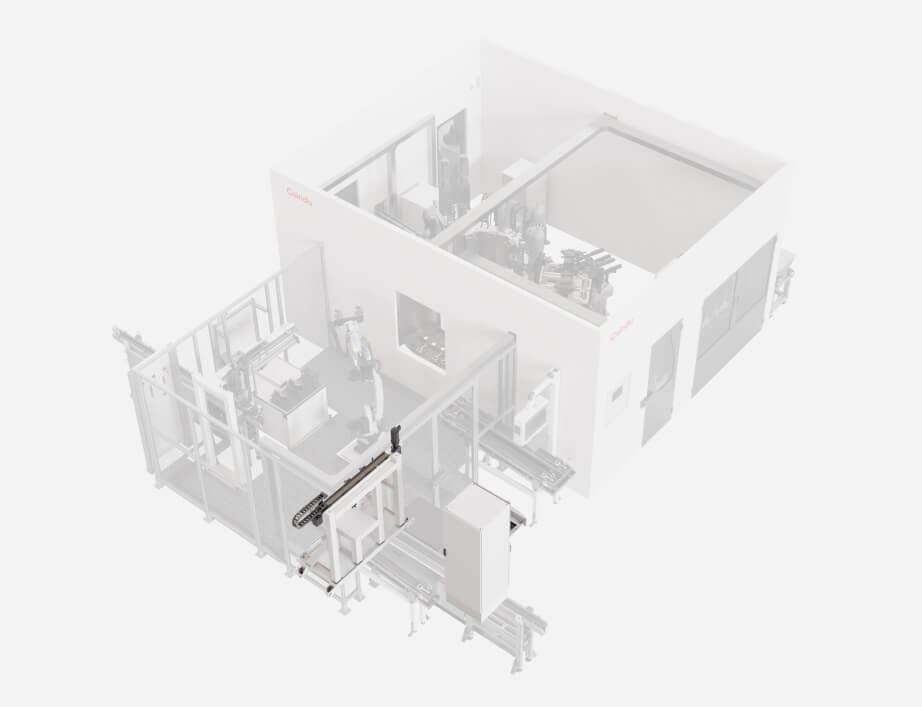

Automation Technologies

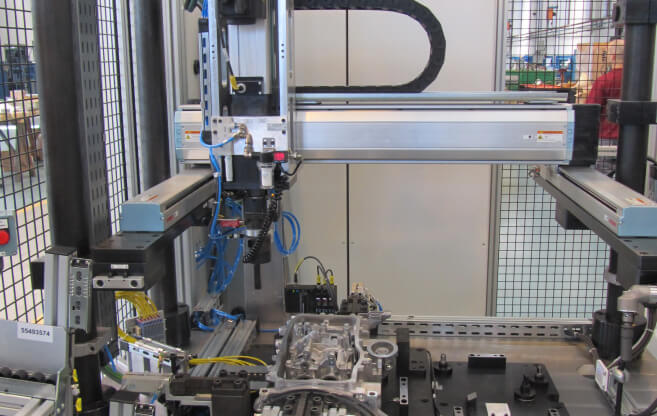

We offer integral solutions to optimize the productivity, being the automation of the loading/unloading and feeding of parts to the production systems a fundamental part of this process.

-

Assembly Technologies

After more than forty years of collaboration with the best manufacturers in the world in order to integrate the most advanced assembly systems in our installations, we are able to offer comprehensive solutions for the assembly and joining of components under the use of diverse technologies.

-

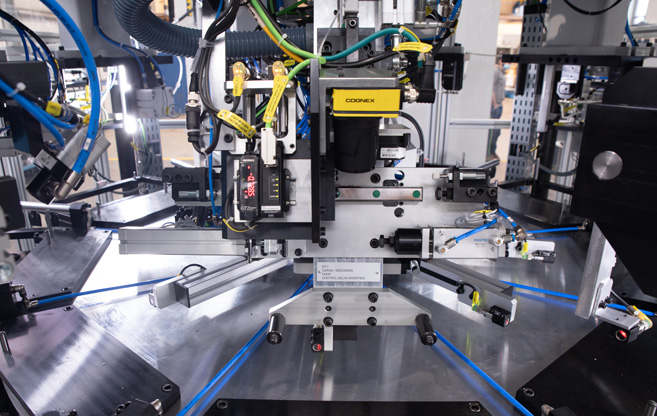

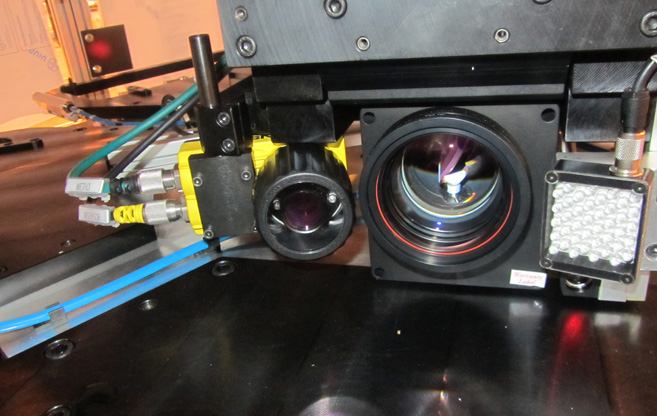

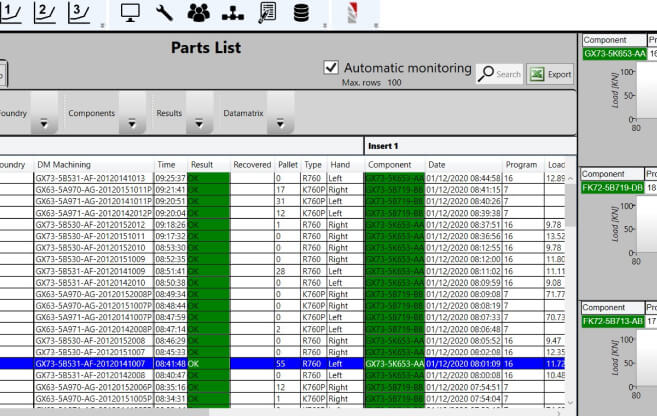

Traceability Technologies

Our cells include the means to completely trace the parts and ensure that the information is recorded for further processing. Some of the technologies used for this purpose include marking, reading and data storage.

-

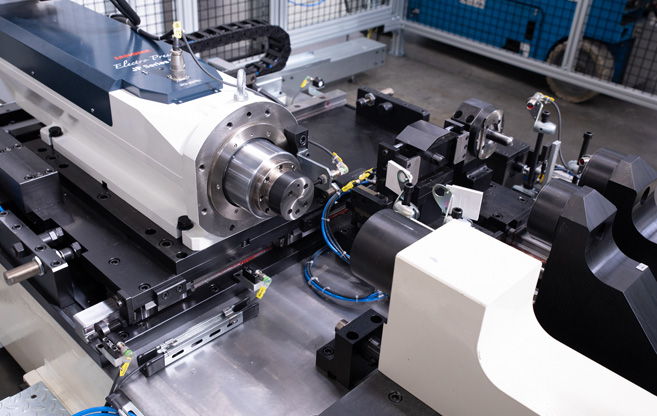

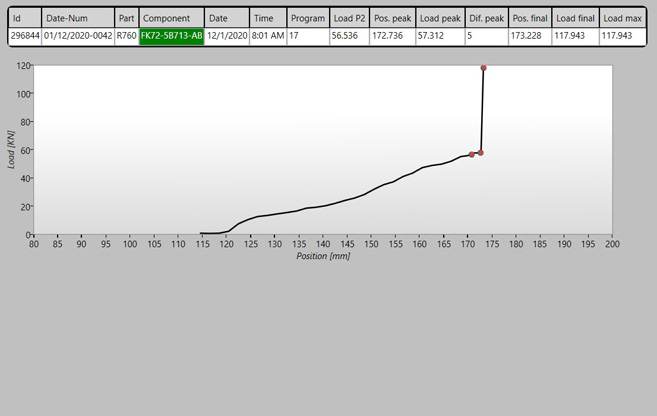

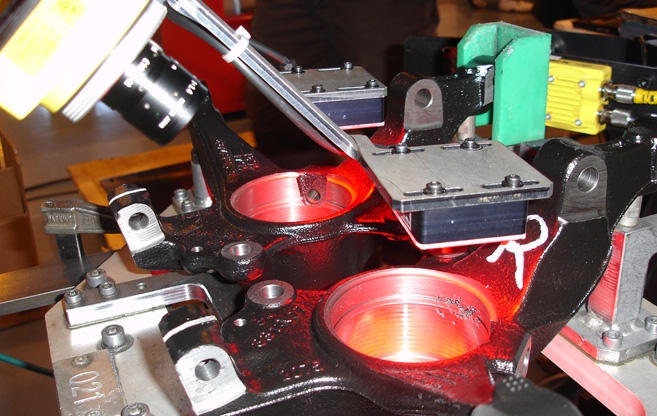

Testing Technologies

Quality assurance in our products and therefore in our customer's final product is an absolute priority for us. In this direction we work to offer the best quality control systems in different areas.

Conveyor

Conveyor

Conveyor

Robot

Feeding

Feeding

Conveyor

Conveyor

Conveyor

Robot

Feeding

Feeding

Pressing

Tightening

Pressing

Tightening

Reading

Gaindu Tracker

Industry 4.0

Reading

Gaindu Tracker

Industry 4.0

Measuring

Vision

Measuring

Vision

Applications

-

CONROD

-

BUSHES

Case studies

Gaindu has collaborated to improve their production processes or undertake complex operations in an efficient way.

MORE ABOUT CASE STUDIESInterested in knowing more how we can help you?

CONTACT US