Testing Technologies

Quality assurance in our products and therefore in our customer's final product is an absolute priority for us. In this direction we work to offer the best quality control systems in different areas.

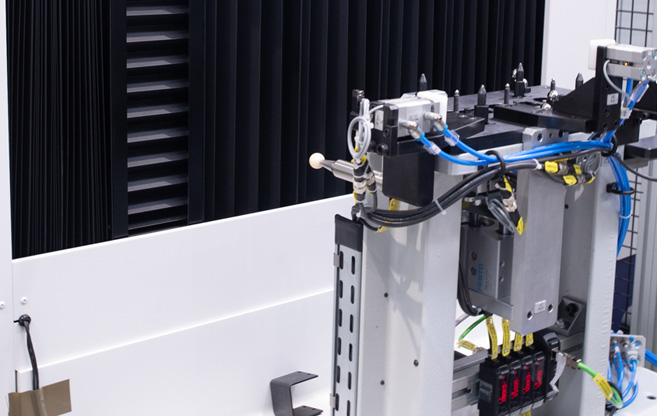

Integrated technologies

Vision

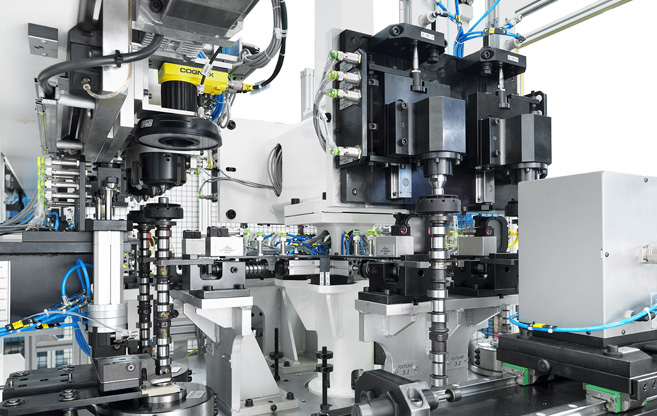

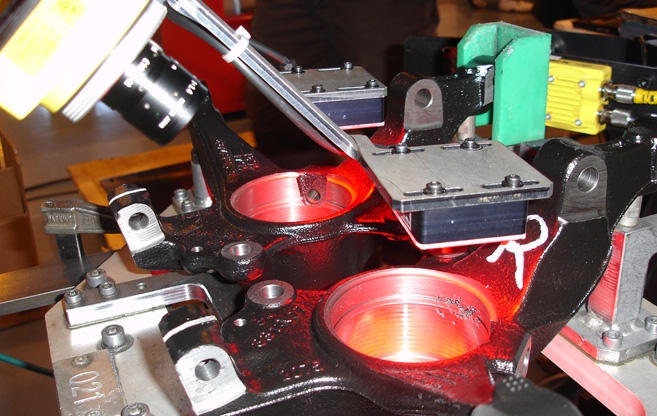

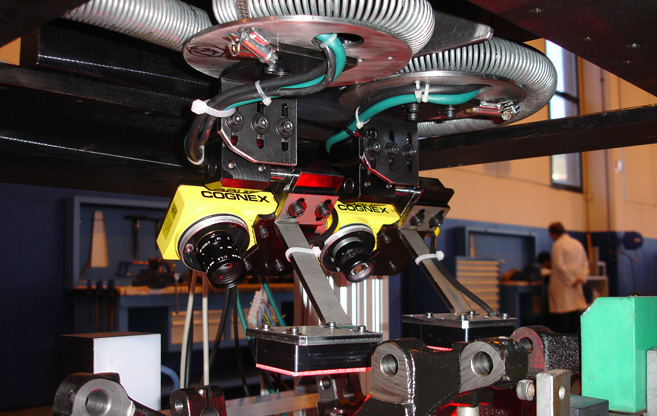

When the conditions of the production line or the floor space available are restricted, there is the possibility of integrating vision equipment to perform various part testing tasks:

- Real-time checking of boring or machining operations on the workpiece.

- Dimensional control of the machined parts.

- Component identification in terms of diversity and positioning.

- Angular or axial components orientation prior to assembly.

- The vision system is carefully studied in each case, analyzing lighting requirements and ambient conditions to ensure a reliable and repeatable process.

TRADEMARKS

Visual Inspection

- As an intermediate control process or as a final part validation process, visual inspection stations are a tool that can be used to check and validate parts.

- At Gaindu we design visual control stations adapted to the needs of the process and the part, with ergonomic functionalities and integrated within our turnkey solutions.

Ultrasonic

- The use of ultrasound for welding inspection is a revolutionary technology in the industry and an important part of quality assurance in the manufacture of components.

- Allows inspection of 100% of the parts with non-destructive technologies.

- With an ultrasonic sensor and the part immersed in water, the complete welding is sampled to verify that is free of internal pores not visible to the human eye that could affect to the durability of the subassembly.

- With these means, the machine can be configured to reject parts from a certain pore size or quantity.

- To offer this type of solution, we have specialist partners that are dedicated to non-destructive testing solutions.

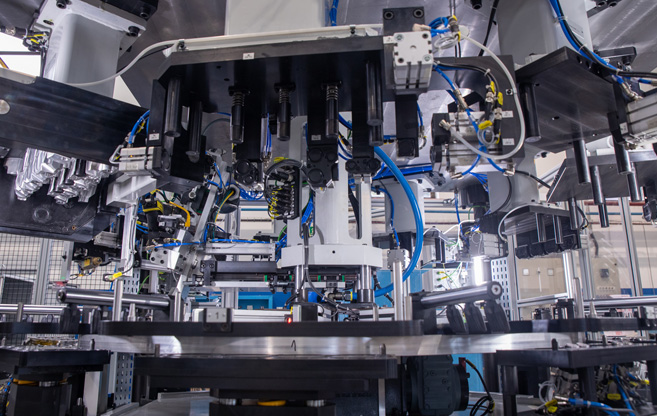

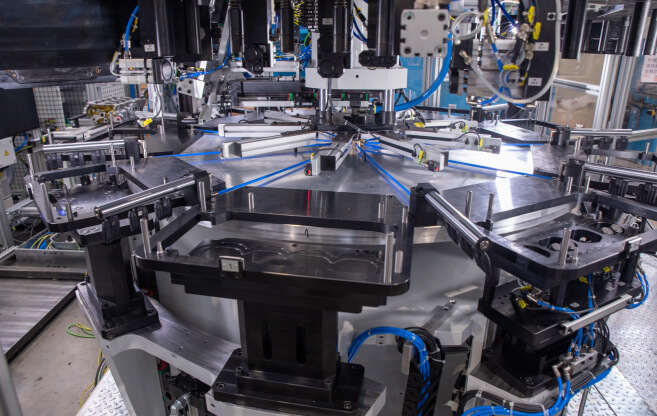

Leak testing

- The leak testing process is an important part of quality assurance in the manufacture of components.

- Checking that the part does not contain leakage above the admissible level is a process that is carried out at various stages of production: after casting, during machining and at the end of the production line.

- There are several methods of leak testing, with alternatives using fluids, air or gas concentration. At Gaindu we work on every possibility to provide our customers with customized solutions.

TRADEMARKS

Post-process Measuring

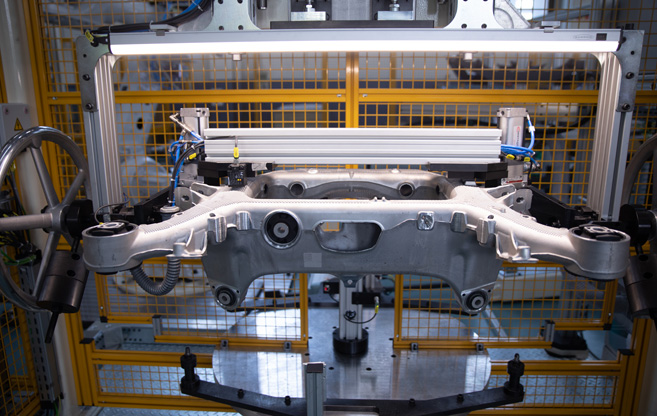

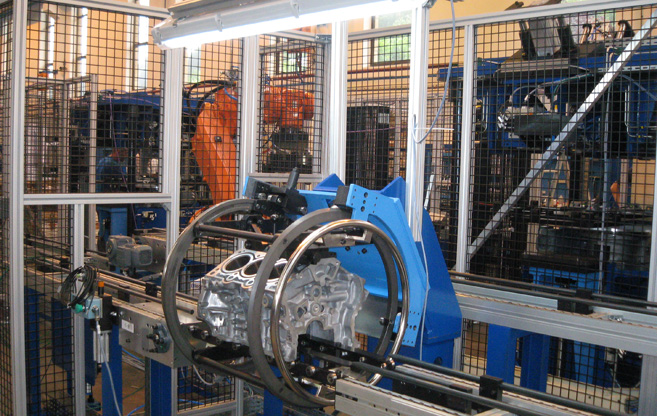

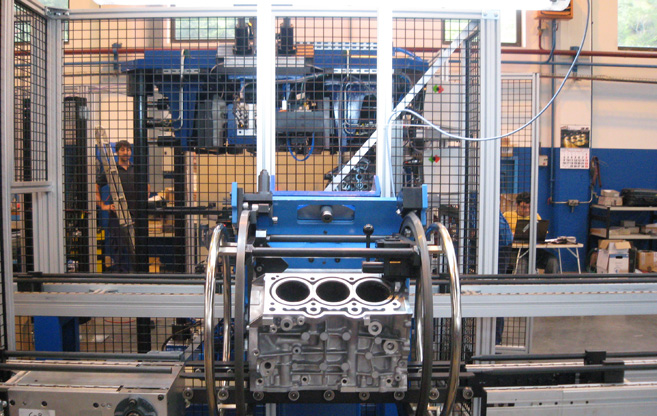

- At Gaindu we offer the possibility of integrating post-process measurement equipment into our robotic cells.

- We integrate gauge systems manufactured by the most recognized brands, on which we integrate our own product-specific tooling to perform dimensional checks after machining.

- Coordinate measuring technology enables precise, flexible and high-speed quality assurance of the parts.

- By eliminating operator’s influence on the final measurement result, we achieve to control and optimize the process effectively.

TRADEMARKS

Interested in knowing more how we can help you?

CONTACT US