Automation Technologies

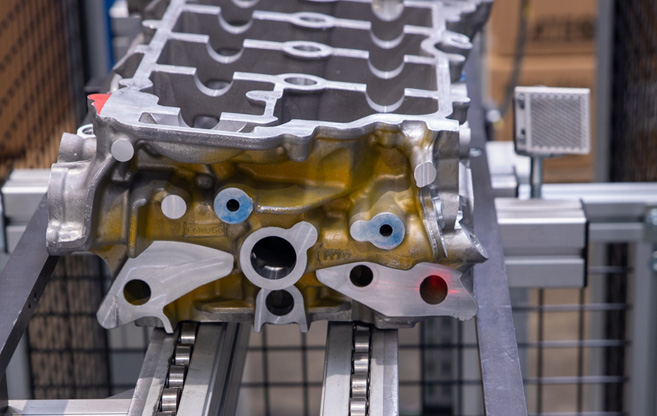

We offer integral solutions to optimize the productivity, being the automation of the loading/unloading and feeding of parts to the production systems a fundamental part of this process.

Integrated technologies

Conveyor

Customized solutions according to the part to be conveyed, its size and required orientation.

- Palletized conveyors

- Roller chain conveyors

- Belt conveyors

Solutions adapted to customer's process / lay-out requirements:

- Separated input and output conveyors

- Conveyor loops including curves

- Palletized conveyors with lifts at each end and two height lanes

We have the capacity to integrate standard third-party equipment as well as conveyors of our own design. Our product development includes pneumatically actuated stoppers of proprietary design.

TRADEMARKS

Feeding

- When it comes to automating processes, automatic component feeding is a fundamental aspect of the cell's autonomy.

- There are several alternatives on the market to automatically feed parts to be assembled. At Gaindu we analyze each case individually to offer the best alternative, taking into account key aspects such as speed, part protection or required orientation.

- Among the alternatives we work with, we make our own design feeders by means of vertical warehouses as well as bowl-feeder or step-feeder integrations, which we customize for each application.

TRADEMARKS

Palletizing

- In order to take the automation of a production cell to the next level, automatic palletizing or depalletizing is a high value-added option that completes any production environment through an automatic input and output of parts.

- Using robots and multi-axis gantries, supported when necessary by advanced vision systems, we design and implement automated solutions for the loading of raw parts. From incoming pallets to the unloading of finished parts onto trays, pallets or transport racks.

- Combining these solutions with the traceability solutions offered by Gaindu, an exceptional level of automation and process control is achieved.

Gantry

Within the variants to automate the loading / unloading of parts or components, we have different solutions using linear gantries with several configurations. Among others:

- 2 axes (XZ)

- 3 axes (X, Z1, Z2)

- 4 axes (X1, X2, Z1, Z2)

- Area gantries (XYZ)

When the required flexibility in automation is higher, it is even possible to integrate robotized linear gantries by mounting multi-axis industrial robots on the horizontal axes.

Design and integration of in-house designed grippers (EOAT), adapted to the needs of each application.

At Gaindu we have the expertise to carry out complete automation of production lines consisting of several CNC machines, assembly, washing, etc... For this purpose, linear gantries are an efficient alternative that frees up space in the plant for the passing of machines / operators.

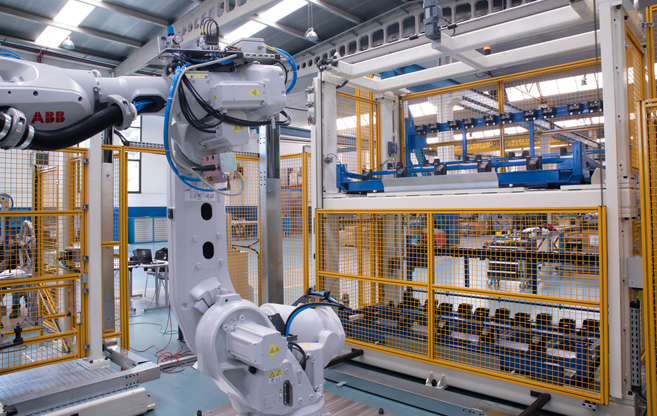

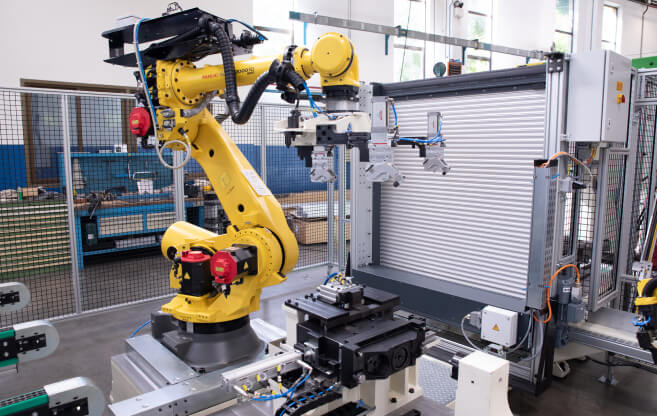

Robot

- When talking about automatic loading / unloading of our machines, integration of six axes and cartesian robots becomes a guarantee for high efficiency solutions.

- We have wide experience in integrating robots of various brands, not only for handling purposes but also as a key tool in some of our assembly standarized solutions.

- Design and integration of in-house designed grippers (EOAT), adapted to the needs of each application.

- Simulation services for the entire robot cycle to assure the process in cycle time conditions and to avoid possible collisions or interferences.

TRADEMARKS

Interested in knowing more how we can help you?

CONTACT US