Challenger

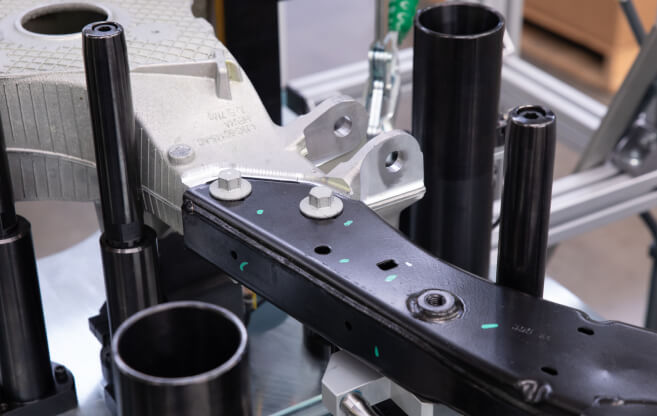

The manufactured machine is capable of processing 3 different conrod models with a minimum changeover time between batches (less than 15 minutes).

The challenge on the project consisted in integrating those references on the same machine, since the size, geometry and characteristics of those are very diverse.

The operation consists of a semi-automatic process, on which an operator loads/unloads the connecting rods as well as pre-loads the screws to the feeder.

OPERATIONS

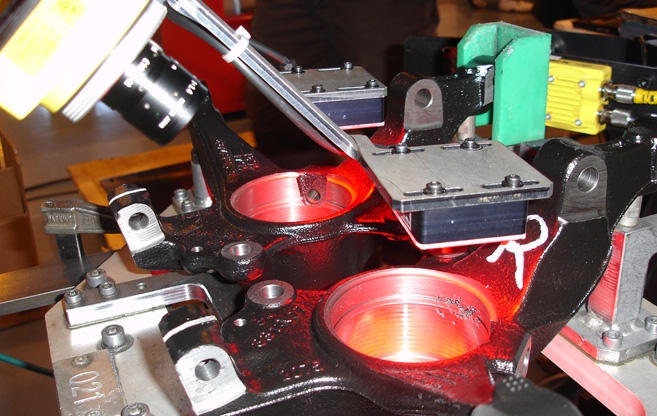

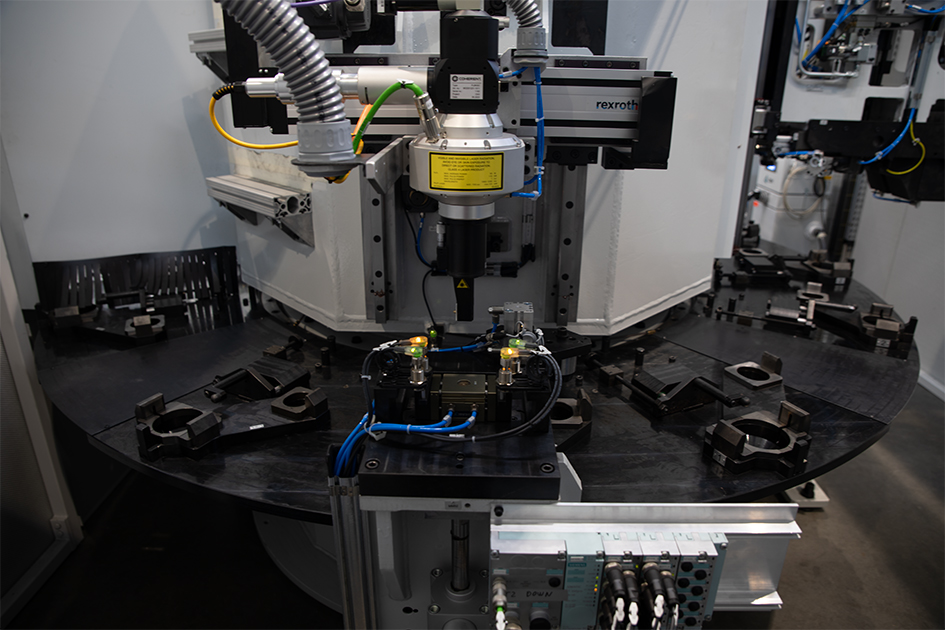

Cracking

Breakage of connecting rods for subsequent assembly, performed on a standard Gaindu Cracking concept, performed by a proprietary electrically driven cracking technology, patented by Gaindu. This technology allows the complete removal of all the hydraulics from the machine, with huge benefits in terms of cleanliness and environment.

OPERATIONS

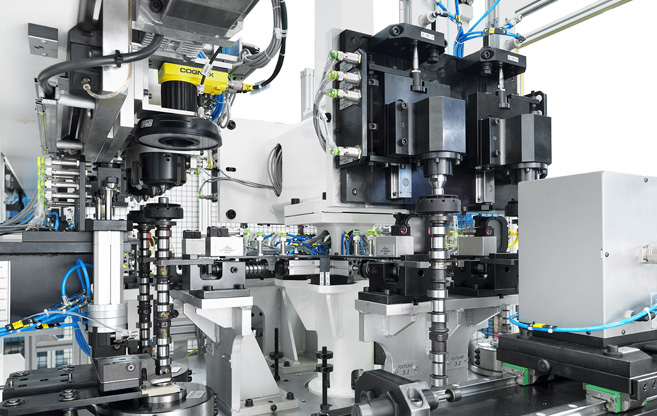

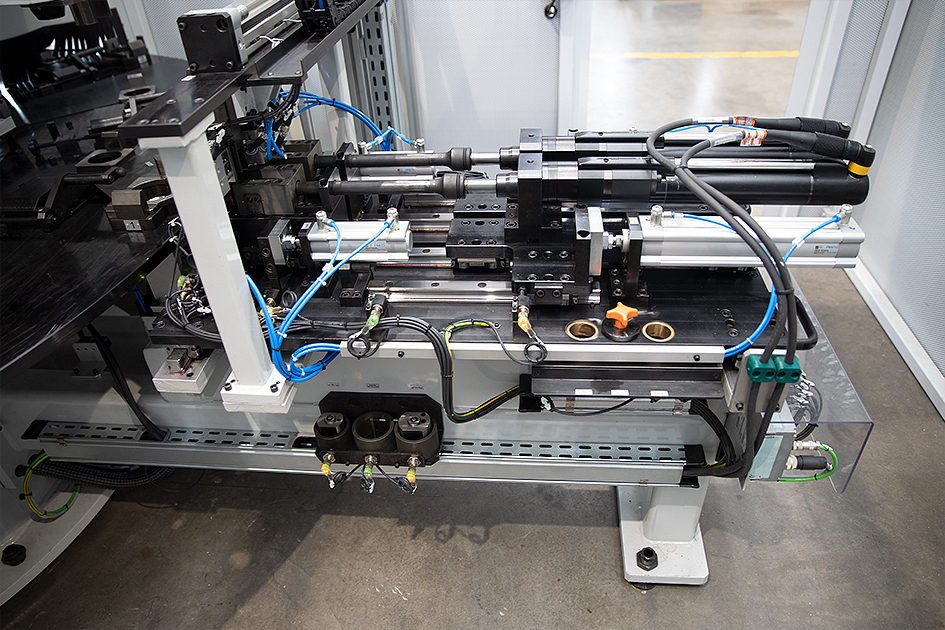

Assembly

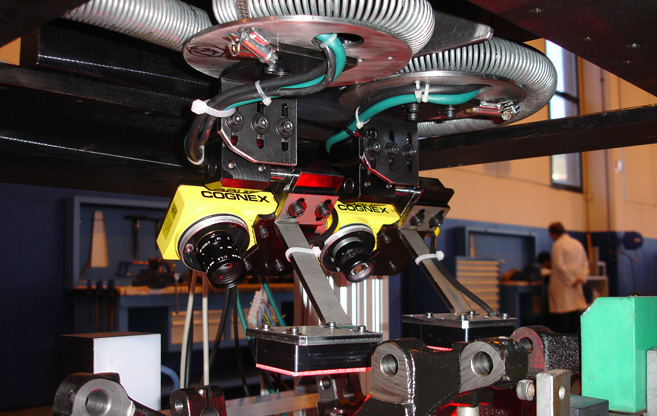

The cracking and assembly machine includes the operation of tightening back the cap and the body. The components are fed by a semi-automatic feeder where we control the type and orientation prior to assembly. All the tightening process performs controlling the torque and angle applied.

Integrated technologies

Interested in knowing more how we can help you?

CONTACT US