Challenger

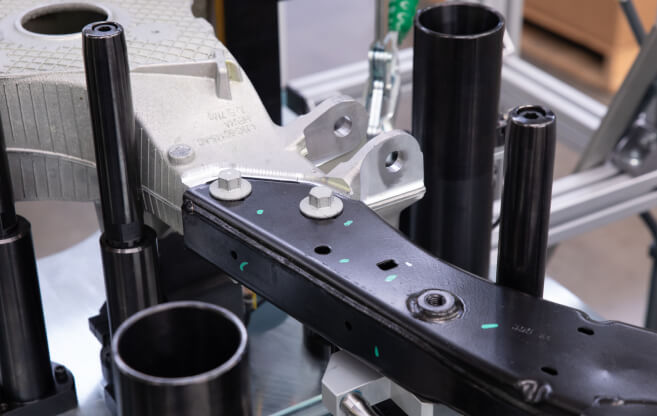

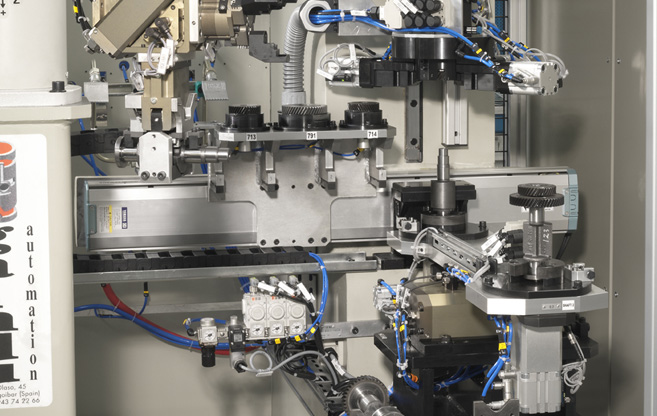

This project posed the challenge of designing a fully automated solution for assembling multiple types of plugs—cup and threaded—into an engine block with high precision and complete traceability.

The complexity came from the need to handle different plug geometries, ensure accurate positioning, apply Loctite sealing with precision, and monitor every stage of the process. The system also needed to meet strict quality requirements, including force and position control during pressing and tightening, and to integrate plug presence verification and brushing operations.

The final solution includes robotic part handling, automatic component feeding, dual Loctite dosing tanks, chromatic sensors, and full data recording linked to each part via 2DM code.

OPERATIONS

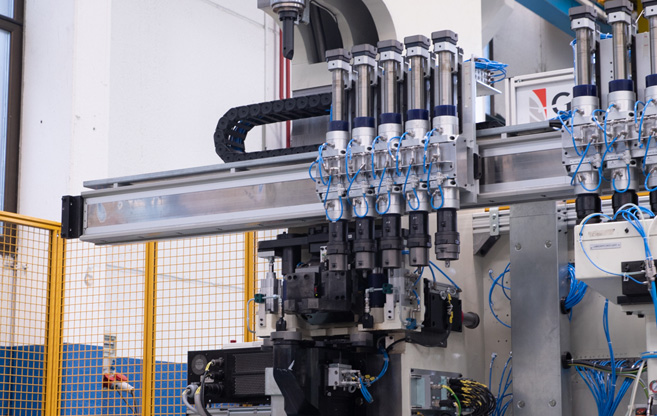

Components Feeding

The cell handles the assembly of three different plug types: one cup plug and two threaded plugs (M12 and M20). All components are automatically supplied by step feeders, which ensure stable feeding flow and correct orientation before assembly. The feeders are designed for high availability and low maintenance, supporting continuous operation in a fully automated environment.

.png)

OPERATIONS

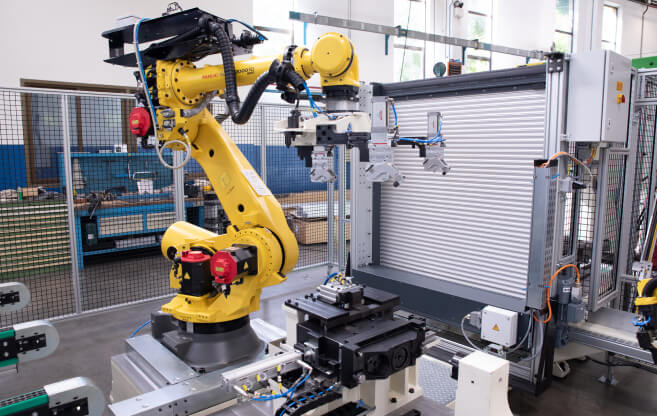

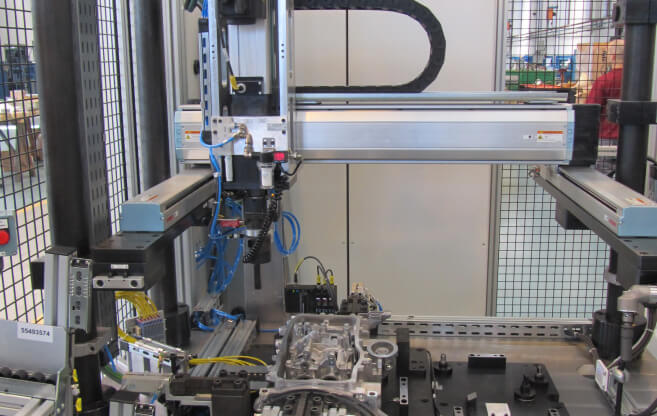

Part Loading / Unloading

A robotized gantry (not part of Gaindu's supply) loads and unloads the cylinder blocks onto an auxiliary table inside the cell. From there, a 6-axis robot transfers the part between all the process stations and back to its original position. The gantry also provides the 2DM code information to the system, enabling full traceability.

OPERATIONS

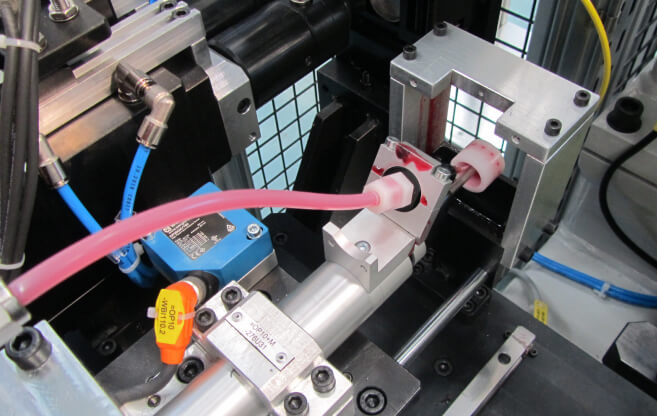

Plug Presence Checking + Loctite Dosing

The process begins with a presence check of the plug holes using pneumatic cylinders with detection pins. Once verified, Loctite is applied into the hole for the cup plug using a rotorspray system. The setup includes two Loctite tanks in tandem, both equipped with level sensors. A chromatic sensor then confirms that Loctite has been correctly dosed.

.png)

OPERATIONS

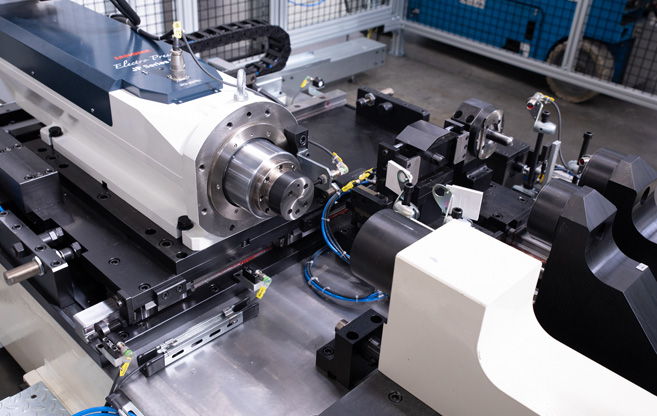

Threaded Plugs Tightening

A second 6-axis robot equipped with two tightening spindles inserts the threaded plugs into six different locations on the cylinder block. A dual-position turning table ensures that the robot can access all faces of the part efficiently, optimizing cycle time and process stability.

Integrated technologies

Interested in knowing more how we can help you?

CONTACT US