Challenger

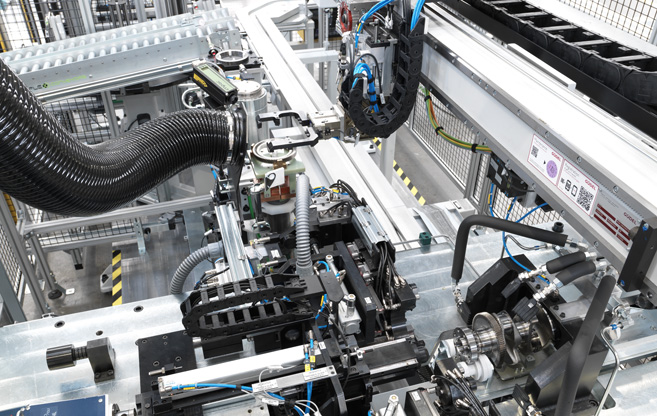

This project required the integration of ring gear and sprocket pressing into crankshafts under strict dimensional and thermal tolerances. The main challenge was to combine induction heating, high-precision component handling, and force-controlled pressing in a compact and efficient automated solution.

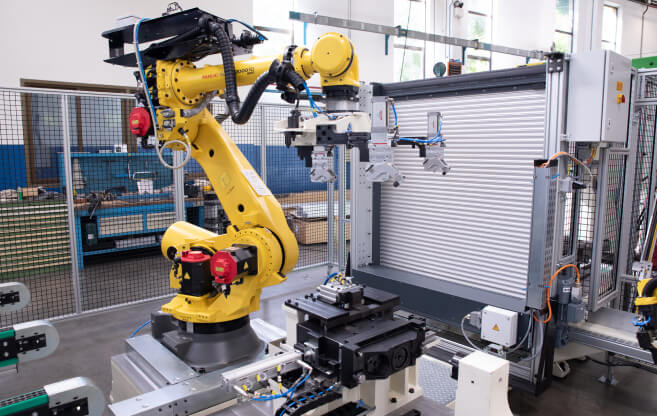

To achieve this, we developed a dual-zone cell involving two 6-axis robots: one for component feeding, measuring and heating; and another for synchronized transfer and insertion. Manual component loading, combined with robotic automation and complete traceability, ensured both flexibility and high-quality results in a demanding production environment.

OPERATIONS

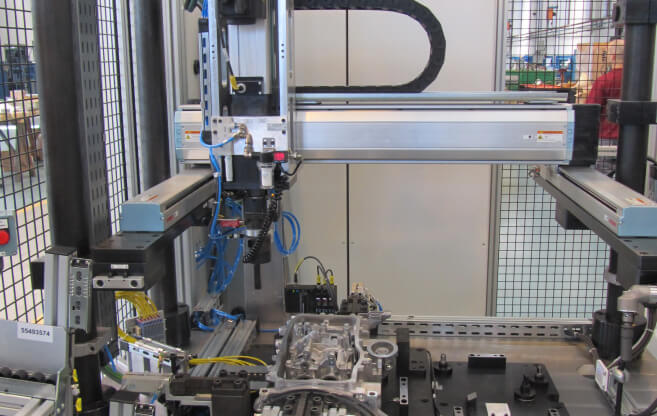

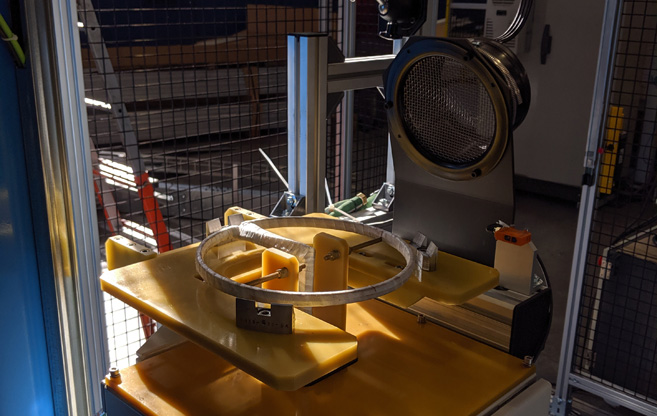

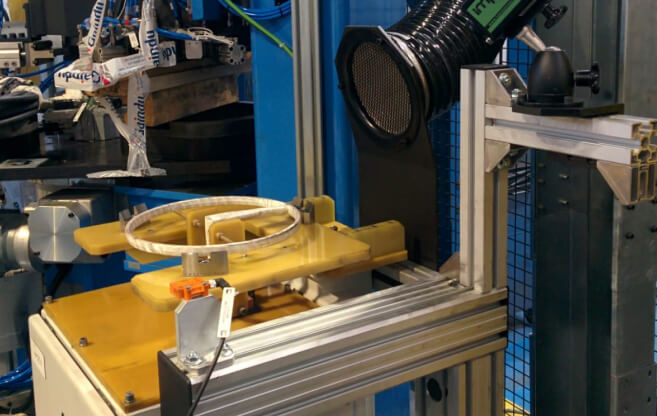

Components Feeding

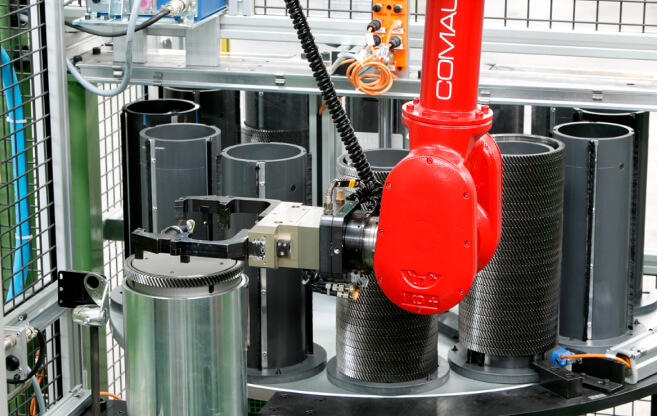

The operator loads ring gears and sprockets into a rotary table equipped with vertical magazines, located outside the robotized cell. Inside the cell, a 6-axis robot picks both components and transfers them to the measuring station, enabling a seamless transition between manual and automated processes.

.png)

.png)

OPERATIONS

Component Insertion

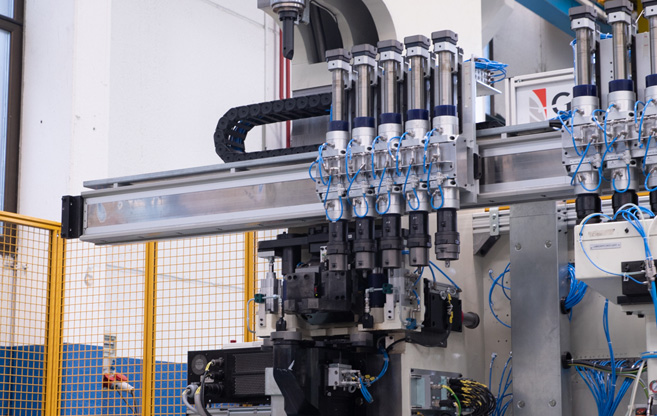

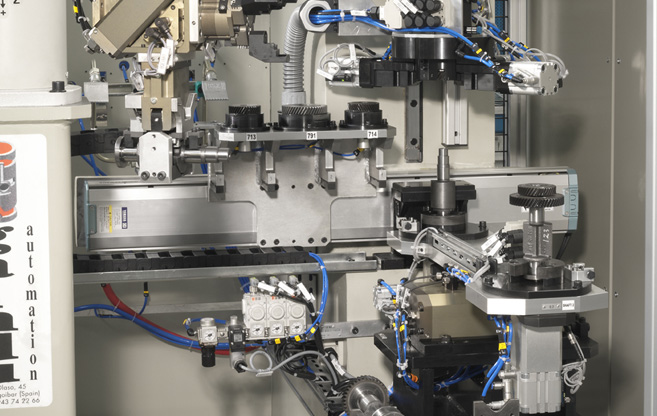

A rotary transfer machine with 3 stations manages the pressing operations:

-

ST1: Crankshaft loading/unloading

-

ST2: Ring gear and sprocket insertion and pressing

-

ST3: Free station

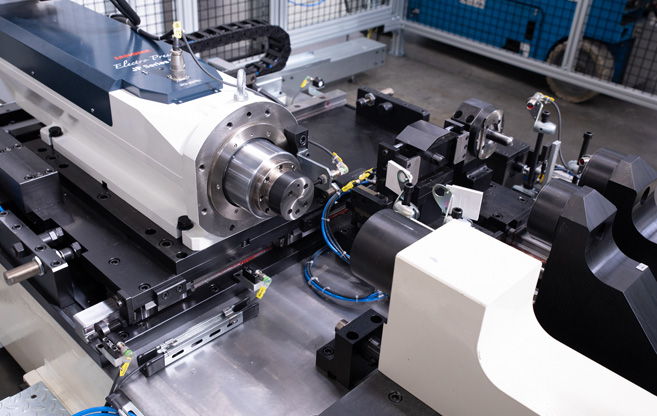

The insertion is performed by an electro-press with force and position control. All process data is recorded and linked to the 2DM code of the part, ensuring full traceability and quality assurance.

Integrated technologies

Interested in knowing more how we can help you?

CONTACT US